A Short History of the Iron Foundry in America: Colonial Beginnings

Early Iron Foundry History in the US

The history of the iron foundry has always been one of the past pushing forward into the future, in a quest for innovation and efficiency. Here at Willman, we understand that journey.

Plentiful Resources and Puritan Industry

As with many things related to our industry, the American iron foundry was born out of necessity. In the mid-1600s there was a growing need for metal containers, tools, and utensils. The early Massachusetts colonies were getting established. The colonists were needing implements to carve farms out of the newly explored landscape. The colonists’ wives were needing pots to cook food to feed their enterprising families. The land was vast and the natural resources seemed limitless. In order to be successful, the colonies were going to need to build their own industries to harness those resources. One of the first of these industries was metalworking.

Saugus Ironworks Forge and Mill, Saugus Massachusetts https://www.asme.org/about-asme/engineering-history/landmarks/7-saugus-ironworks

In those early days of the European colonization of North America, it was a four-month round trip trek to the closest foundry. This made stock orders a hardship and special orders rare. As the population of the colonies grew the issues became worse. The first-generation Americans were even more dissatisfied with the situation than their parents had been and sought a solution. John Winthrop, Jr. sailed to England in 1640 and raised capital to open the first foundry in the British Colonies. An avid chemist and amateur scientist, the future governor of Connecticut saw the incredible benefit of establishing an iron foundry in the colonies. He chose Braintree, Massachusetts for the location. Construction for the first foundry began in 1644 and was completed the next year. However, it ran into issues immediately.

America’s First Iron Foundry

The location Winthrop chose was convenient but proved to be unsuitable for the foundry as it had an inadequate water supply for powering the equipment connected to the foundry. A lack of iron ore immediately available in the local area also made the location ill-advised. The consortium of investors (called the “Undertakers”) replaced Winthrop with a merchant named Richard Leader. Having a good grasp of metallurgy and a better understanding of the needs of a foundry, Leader relocated the Braintree Foundry to Lynn, Massachusetts on the Saugus River. This proved to be a far better choice for the business, which flourished on the banks of that river for several years.

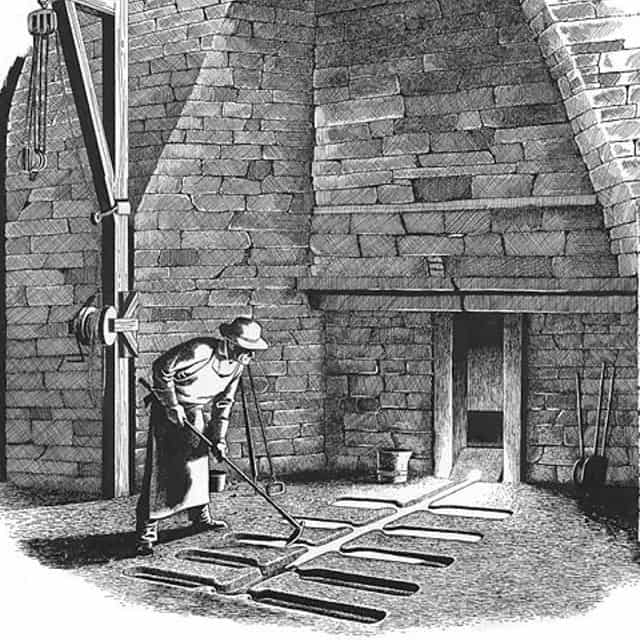

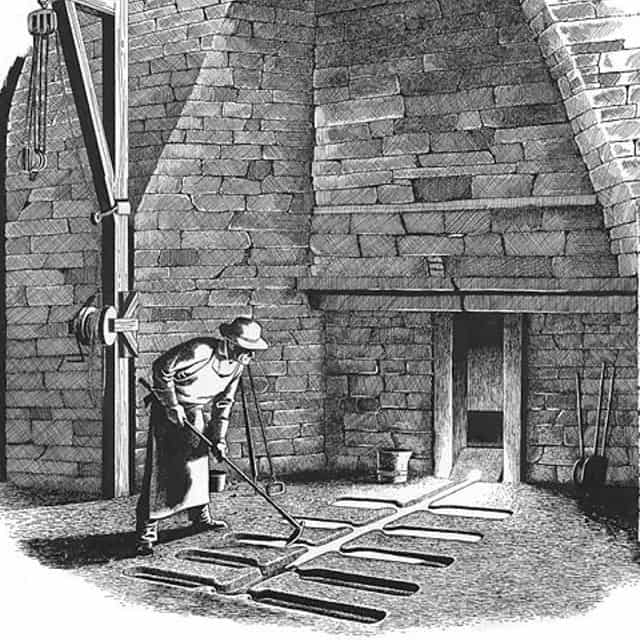

Molten iron separated out into pig iron bars. https://www.nps.gov/articles/000/iron-workers.htm

When the newly-moved iron foundry started operations in 1646, it was already innovating the iron-working process. Limestone was used for flux material in foundries at that time. Unfortunately for Leader, limestone was not available in the area, which would have kept them from processing any iron at all. Through a process of trial and error, the new foundry manager and his workers discovered that an igneous rock called gabbro would function well as a flux material in the melting process.

Early Failure but Continued Success

After Leader left to pursue other interests due to disagreements with the Undertakers, the foundry was mismanaged until it failed and was closed in 1670. Regardless of the ignominious end for the first foundry in North America, the fires of the American iron industry had been lit!

A little over 130 years later there were nearly eighty foundries in the American colonies. Foundries required rivers for the hydro-powered equipment and forests to supply the trees for charcoal, both of which were plentiful in the eastern part of North America. In the 1700s, colonial foundries began moving away from the bogs and swamps where the initial iron ore deposits were found. The larger iron deposits found in New York state and eastern Pennsylvania led to foundries moving to those states and northern New Jersey.

The Early Importance of the American Iron Industry

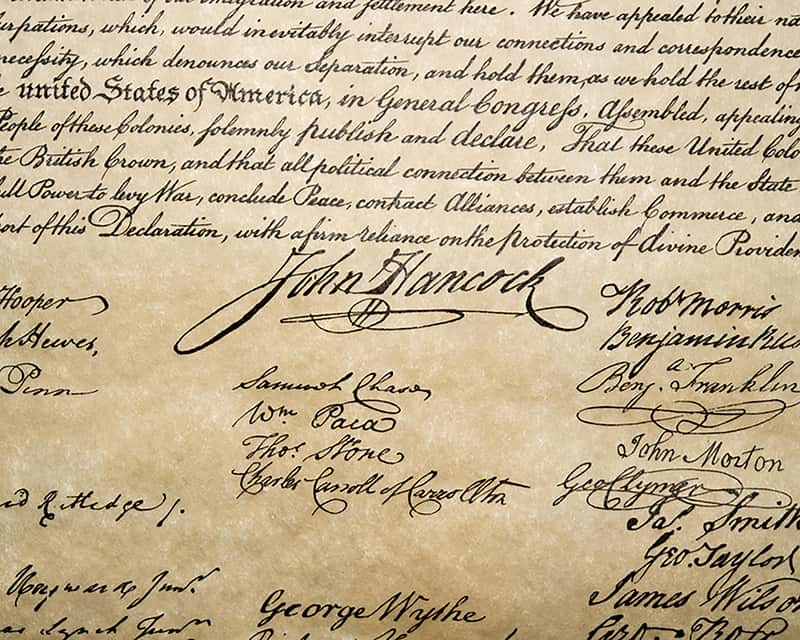

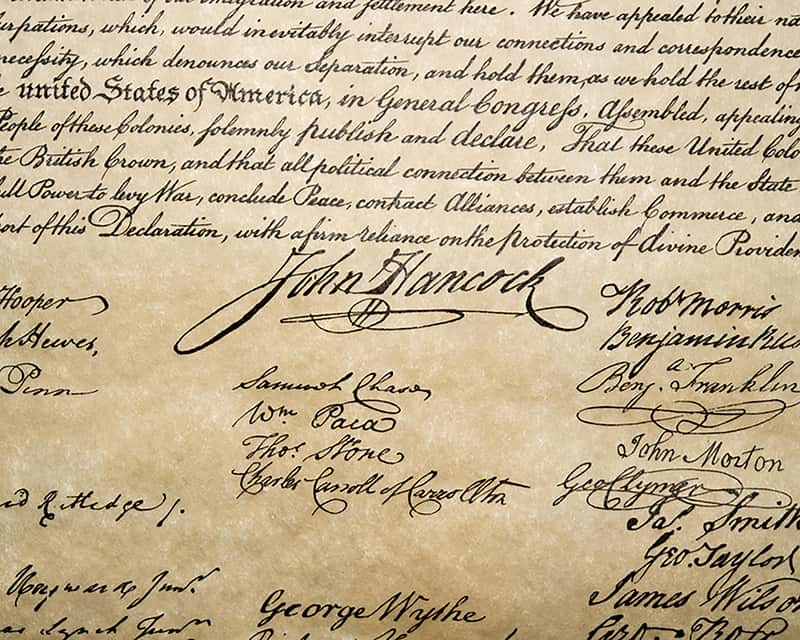

Signers of the Declaration of Independence https://howeenterprise.com/1776-2/declaration/

By the late 1700s, foundry owners were among the most influential people in the colonies as metalworking became a critical industry. Seven out of the 56 men who signed the Declaration of Independence own and operated furnaces or foundries. When the first shots of the American Revolutionary War were heard the colonies were already producing over 15% of the world’s iron…more than England itself. This had pushed England to attempt to limit the iron and ironworks produced by the colonies. The Iron Act of 1750 had severely limited the colonial foundries regarding what they could produce and hampered furnaces such as Charles Carroll’s Carrollton Furnace from expanding their operations. With their freedom to innovate and expand curtailed, these men found common cause with many others that wished to separate from England.

Our Celebration of Innovation and Freedom

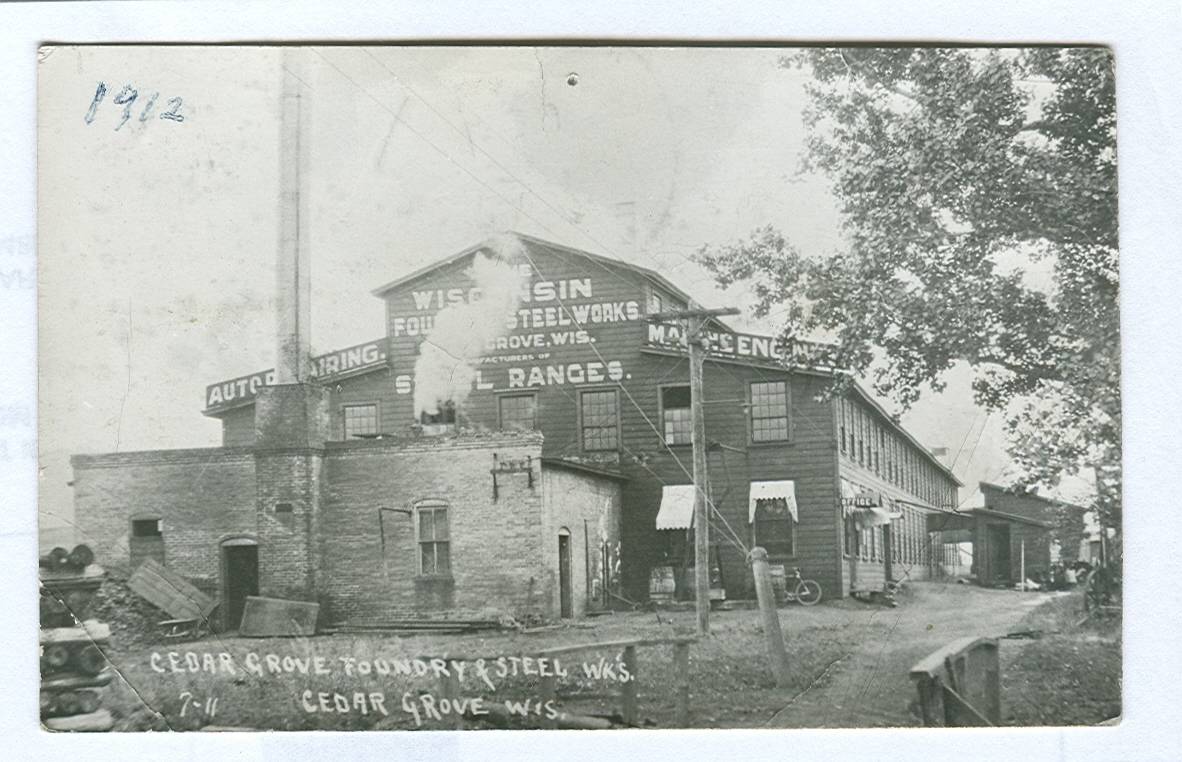

We celebrate those founding fathers and their dedication to innovation and freedom. The iron foundry founders and workers put their blood, sweat, and tears into improving the quality of their products and workplace. Innovation and efficiency followed them every step of the way. That same tradition was a part of our direction and purpose for the first one hundred years of operation and it will be for the next. Since 1899, our foundry has been dedicated to these ideals. We want to put them to use for you.

Contact Us Today!

Contact Us Today!

Contact us today to see how we can help your company. Our knowledgeable staff is available to answer your questions or put together a quote. We can also plan a tour of our facilities where you can watch our knowledgeable staff work diligently to provide the best quality parts in the industry.

Choose Willman, choose quality!