Vannoccio Biringuccio: A Renassance Pioneer in Iron Casting

A Look at the History of Vannoccio Biringuccio and Iron Casting

Iron foundries have played a significant role in the development of modern industry. For centuries, humans have been able to mold iron into a variety of forms, creating everything from weapons to tools to infrastructure. One individual who had a major impact on the development of iron casting was Vannoccio Biringuccio, an Italian metallurgist who lived during the 16th century.

Iron foundries have played a significant role in the development of modern industry. For centuries, humans have been able to mold iron into a variety of forms, creating everything from weapons to tools to infrastructure. One individual who had a major impact on the development of iron casting was Vannoccio Biringuccio, an Italian metallurgist who lived during the 16th century.In this article, we will explore the history of iron foundries, the contributions of Vannoccio Biringuccio, and the role that iron casting continues to play in modern society.

History of Iron Foundries

Iron foundries have a long history dating back to ancient civilizations such as the Greeks and Romans. However, it wasn’t until the Middle Ages that iron casting began to be used extensively for industrial purposes. During this time, iron was used to make weapons, tools, and other essential items.

Iron foundries have a long history dating back to ancient civilizations such as the Greeks and Romans. However, it wasn’t until the Middle Ages that iron casting began to be used extensively for industrial purposes. During this time, iron was used to make weapons, tools, and other essential items.The first European iron foundry was established in 1473 in Austria. Over the next few centuries, iron casting spread throughout Europe, with the Industrial Revolution in the 18th and 19th centuries accelerating the growth of the iron industry. Iron foundries were established across Europe, the United States, and other parts of the world, leading to the production of a wide range of iron products, including machinery, railroads, and bridges.

Vannoccio Biringuccio and the Development of Iron Casting

Vannoccio Biringuccio was an Italian metallurgist who lived during the 16th century. He was born in Siena, Italy, in 1480 and spent much of his life working in various iron foundries across Europe.

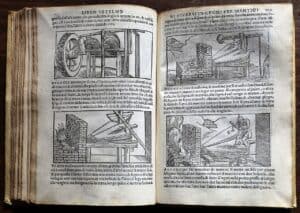

Biringuccio was a pioneer in the field of metallurgy and made significant contributions to the development of iron casting. His most notable work was a book called “De la Pirotechnia”, which was published in 1540. This book is considered one of the most important texts on metallurgy from the 16th century and provides a detailed account of the various techniques used in iron casting.

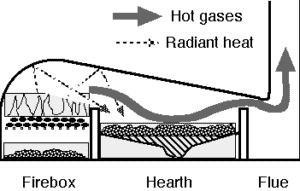

Biringuccio was a pioneer in the field of metallurgy and made significant contributions to the development of iron casting. His most notable work was a book called “De la Pirotechnia”, which was published in 1540. This book is considered one of the most important texts on metallurgy from the 16th century and provides a detailed account of the various techniques used in iron casting.In “De la Pirotechnia”, Biringuccio describes the process of smelting iron ore and the various methods used to cast iron into different shapes. He also provides a detailed account of the different types of furnaces used in iron casting, including the blast furnace and the reverberatory furnace.

Biringuccio’s work was groundbreaking in its time and helped to lay the foundation for modern metallurgy. His detailed descriptions of the various techniques used in iron casting allowed other metallurgists to build on his work and make further advancements in the field.

The Role of Iron Casting in Modern Society

Iron casting continues to play a significant role in modern society. Iron products are used in a variety of industries, including construction, transportation, and manufacturing. For example, iron is used to make everything from automobiles to bridges to household appliances.

One of the main advantages of iron casting is its versatility. Iron can be cast into a wide range of shapes and sizes, making it an ideal material for a variety of applications. Additionally, iron is durable, strong, and resistant to corrosion, making it a popular choice for outdoor applications.

One of the main advantages of iron casting is its versatility. Iron can be cast into a wide range of shapes and sizes, making it an ideal material for a variety of applications. Additionally, iron is durable, strong, and resistant to corrosion, making it a popular choice for outdoor applications.Despite its many advantages, iron casting is not without its challenges. One of the main challenges is the environmental impact of iron production. Iron production is energy-intensive and can generate significant amounts of greenhouse gases, including carbon dioxide and methane.

New Solutions to Old Problems

To address these challenges, the iron industry has been working to develop more sustainable production methods. For example, some iron foundries are using renewable energy sources, such as wind and solar, to power their operations. Additionally, new technologies are being developed to reduce the environmental impact of iron production For instance, some foundries are experimenting with using electric arc furnaces, which use electricity to melt scrap metal instead of coal or coke. This method can significantly reduce greenhouse gas emissions associated with iron production.

To address these challenges, the iron industry has been working to develop more sustainable production methods. For example, some iron foundries are using renewable energy sources, such as wind and solar, to power their operations. Additionally, new technologies are being developed to reduce the environmental impact of iron production For instance, some foundries are experimenting with using electric arc furnaces, which use electricity to melt scrap metal instead of coal or coke. This method can significantly reduce greenhouse gas emissions associated with iron production.Moreover, there is a growing interest in using recycled iron, or scrap metal, in iron casting. Using recycled iron not only reduces the amount of waste in landfills but also reduces the need for virgin iron ore. This, in turn, reduces the energy required for iron production and the associated greenhouse gas emissions.

In conclusion, iron foundries have played a vital role in the development of modern industry, and Vannoccio Biringuccio’s contributions to the field of metallurgy have been invaluable. While iron casting continues to face environmental and safety challenges, the industry is working to develop more sustainable production methods and implement strict safety protocols. With its versatility and durability, iron casting is likely to remain a popular choice for a wide range of applications in the years to come.

Willman Means Quality

Willman is proud of these innovators in the iron and steel industry. Without their contributions to these important industries, we would not have some of the things that we take for granted today. Our engineers, specialists, and technicians are inspired by their ingenuity and motivated to build on their success.

Willman is proud of these innovators in the iron and steel industry. Without their contributions to these important industries, we would not have some of the things that we take for granted today. Our engineers, specialists, and technicians are inspired by their ingenuity and motivated to build on their success.Call us today to find out how our dedication to excellence can benefit your company and your customers. Our knowledgeable staff and state-of-the-art facilities will provide the quality that you deserve!