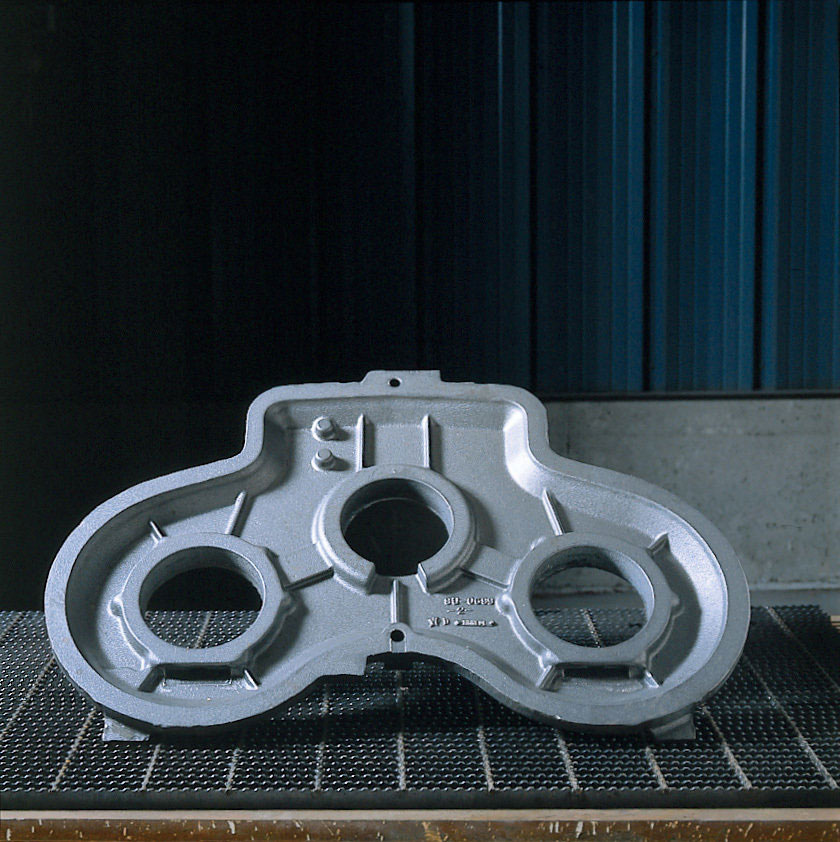

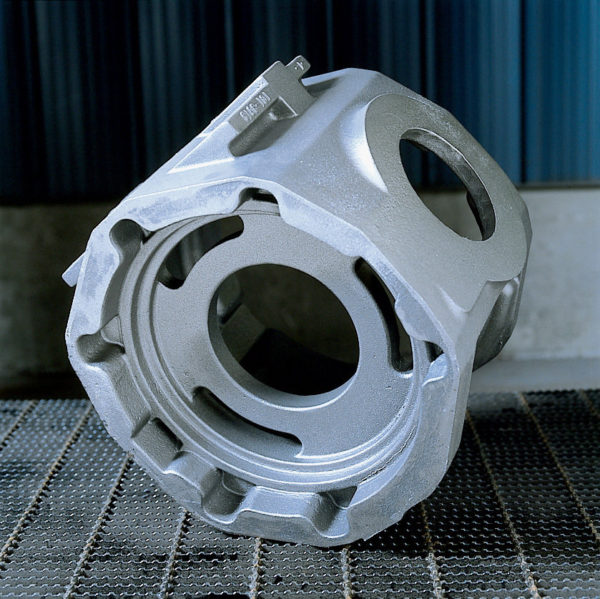

Green Sand Molding

Our Hunter, Pin Lift, and BMM molding machines can produce green sand castings in quantities from 10 to 5,000+ annually.

Our highly flexible production facilities in green sand molding allow us to produce casting volumes from prototype to 5,000+ per year using horizontally parted molding machines. Willman Industries green sand molding lines include: Hunter-20”x 24” (8/8), Cope & Drag-Pin Lift 30”x 30” & 36”x 36” & BMM 42”x 42” & 42” X 60” (20/20).

Willman Industries’ green sand molding offers the distinct advantage of using green sand for larger casting production, that many foundries would need to run in no-bake. We are able to produce larger castings efficiently, in green sand, on the BMM molding line while maintaining high quality standards. We are continually improving our facilities and optimizing them to increase our production levels and improve quality.