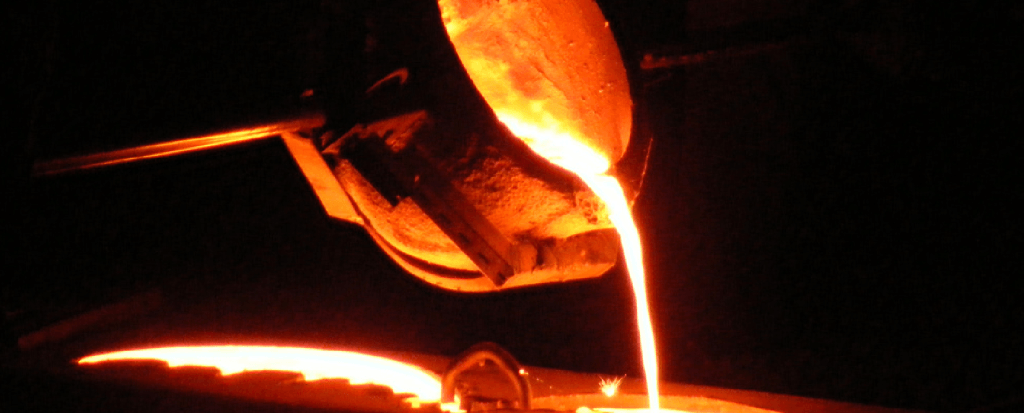

Gray Iron: Lower Cost and Higher Vibration Dampening

Gray Iron – Grades Produced:

(For Gray Iron, the tensile strength defines the grade.)

(Grades divided by Classes as defined by ASTM and Meehanite Metal Corp)

Class 20 / GE20 (20,000B)

through

Class 55/ GM60 (55,000B)

Ductile Iron: Higher Strength and Better Performance

Ductile iron, developed as recently as the middle of the 20th century, is made using a Magnesium ladle addition to condense the graphite flakes into nodules during solidification. With the graphite in this form, the resulting metal behaves (to a much greater degree) according to the properties of the ferritic or pearlitic matrix surrounding the nodules. The material properties are no longer simply dominated by brittle fracture along the graphite flakes in gray iron. The resulting metal has higher strength than gray iron and will exhibit plastic deformation before failure. Therefore, a Ductile Iron casting will behave in a manner that is in between the rigid and brittle behavior of a Gray Iron casting and the soft and very ductile behavior of low carbon steel. Ductile Iron, while being more difficult to manufacture than Gray Iron, is still much cheaper to produce than steel. This combination makes Ductile Iron castings the best choice for ferrous casting components for which the stress, strain, and fatigue requirements are met by one of its many and diverse standard grades.

Willman Industries can supply grades 60-40-18 through 100-70-03 as cast (w/o heat treatment).

Ductile Iron – Grades Produced

(Grades of Ductile Iron are defined by their Tensile Strength, Yield Strength, and Elongation.)

Grades divided by Classes as defined by ASTM and Meehanite Metal Corp

60-40-18 / SF60

65-45-12 / SF60

80-55-06 / SP80

100-70-03 / SH100

Ductile Iron vs Gray Iron and Steel

Choose Willman for Quality and Dependability!

Willman Industries has open capacity for new projects for both large and small castings. We produce most of the commonly used grades of gray iron and ductile iron. So send us the drawings and specifications of your latest project today and we will provide timely feedback and/or quotations. If you are experiencing a crisis with your current supply chain, call us. We have the management horsepower to quickly step into the breach.

Call us today for a quote or a tour of our facilities!