Solution Strengthened High Silicon Ferritic Ductile Cast Iron (SSFDI) is

This newer grade (most other grades of cast iron date to the decades surrounding WWII and are well over 50 years old) tolerates a higher amount of pearlite and carbide stabilizing elements without the generation of embrittling pearlite or carbides in the microstructure. The presence of Manganese, Chromium, and Vanadium do not significantly influence the elongation.

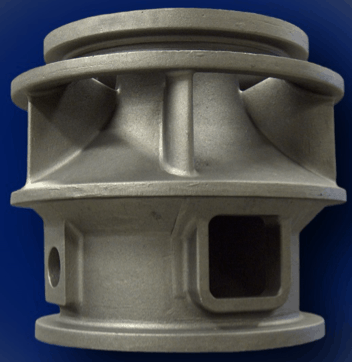

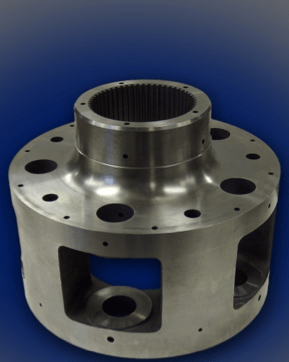

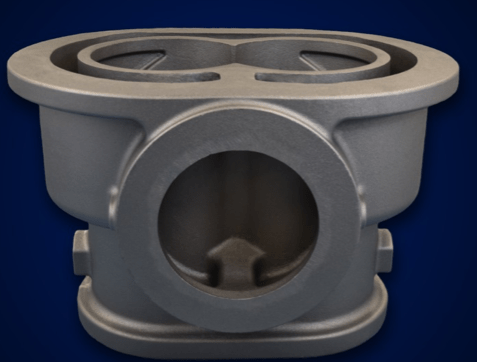

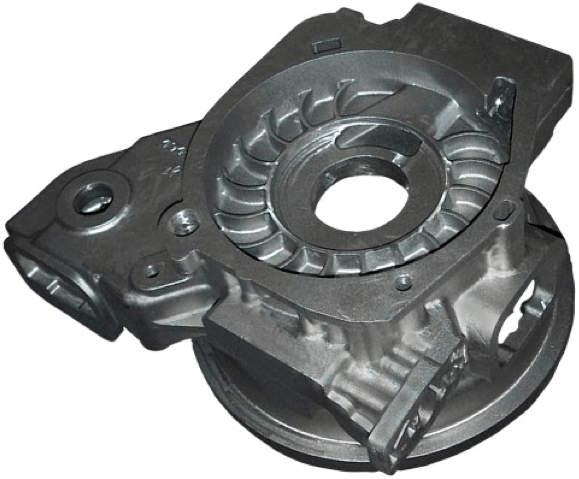

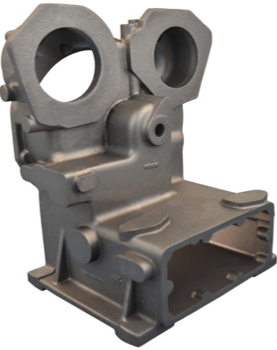

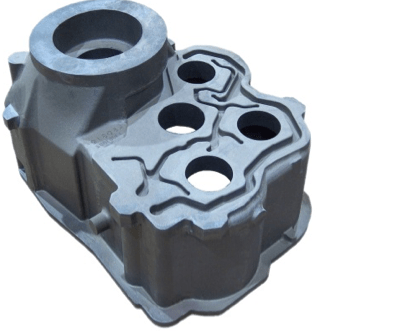

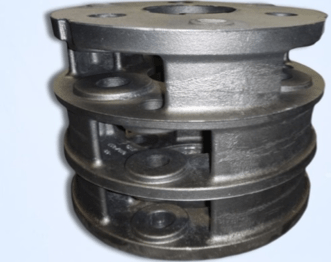

SSFDI products are Ideal for drive train components – brackets, bearing housings, axle housings as well as transmission parts, carriers, and housings where elongation would be required or preferred.

SSFDI is a possible alternative to 90-60-20 steel castings. You can use it to replace 60-40-18 in applications where additional elongation would be required based on engineering requirements. In addition, the hardness and mechanical properties are extraordinarily uniform throughout all the casting sections.

An advantage of SSFDI is the lower cost in machining due to lower tool wear, allowing for 50-60% longer tool life than more common ferritic-pearlitic grades. These grades can be produced as cast with greater uniformity of casting properties than the original ductile iron grades shown above.

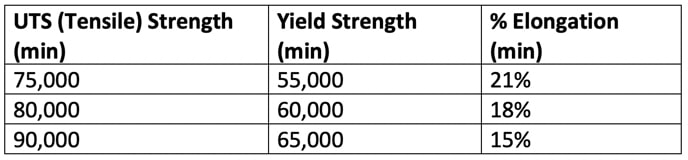

Willman Industries has perfected SSFDI creating a product we call Solution Strengthened Ductile Iron. Willman Industries has developed three new tentative specifications because the results just don’t fit within the previous standards. The new specifications are as follows:

Properties of SSDI “As Cast”-No Heat Treatment required:

These new grades do not exhibit the section sensitivity of the original ductile iron grades. Also, the hardness and mechanical properties are extraordinarily uniform throughout all the casting sections.

To simplify the comparison, the middle grade (80-60-18) meets the elongation requirement (18%) of the standard 60-40- 18 but possesses higher tensile and yield strength. However, for those solely interested in elongation, there is a new grade, 70-55-21, which has higher elongation as well as higher yield and tensile strength. It should also be noted that the yield to tensile strength ratio of these new grades is typically 75% whereas the first generation has a ratio of about 65%. This gives engineers more leeway in design since the limit of proportionality is higher for any given tensile. Similarly, the fatigue strengths are higher at any given elongation.

We should note you should not use Solution Strengthened Ferritic Ductile Cast Iron SSFDI where welding is needed, in applications where flame or induction hardening is required, or in an application where the casting may be exposed to very high temperatures as SSFDI does not have alloy content to allow for this.