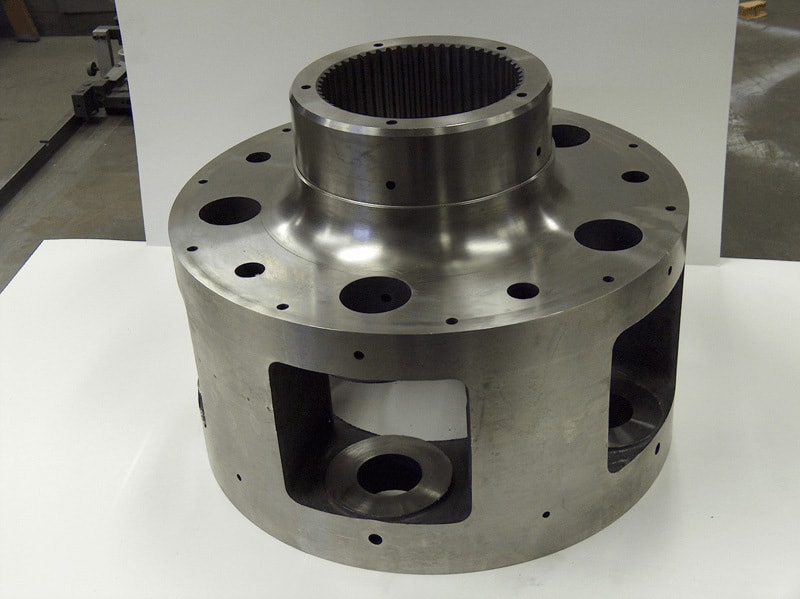

Willman Industries’ Ductile Iron Foundry produces a family of cast graphitic irons possessing high strength, resistance to shock and ductility. Ductile iron castings resist fracture even when being bent, twisted or deformed. Its strength, toughness and ductility greatly exceed that of standard grey irons and its properties are very similar to many grades of steel. Additionally Ductile Iron has a lower cost of casting procedure compared to steel; as well as the advantage of design flexibility. (If you are wondering, “What is Ductile Iron?” check out our link.)

Willman Industries’ Ductile Iron Foundry produces a family of cast graphitic irons possessing high strength, resistance to shock and ductility. Ductile iron castings resist fracture even when being bent, twisted or deformed. Its strength, toughness and ductility greatly exceed that of standard grey irons and its properties are very similar to many grades of steel. Additionally Ductile Iron has a lower cost of casting procedure compared to steel; as well as the advantage of design flexibility. (If you are wondering, “What is Ductile Iron?” check out our link.)

Ductile Iron castings have good toughness and high elasticity and can be considered comparable to carbon steel in strength. It is often used to produce iron parts which require high strength, toughness and complex shapes. At Willman Industries Ductile Iron Foundry, our castings perform consistently in strength and toughness because we use the best raw materials.

Ductile Iron’s cast performance is better than steel and is normally used for castings requiring larger load and a higher mechanical complexity. As the second foundry in the country to produce ductile iron we have know about its superior characteristics since 1949. Back in the early days of Ductile Iron people traveled from all over the world to learn how to make Ductile Iron from Willman Industries and even today we are the experts in ductile Iron castings.

Our Willman Engineering Department (WED) engineer the gating and rigging of our equipment to assure quality and consistency in every pour. We control the metallurgy in the furnace, in each ladle, in each casting and check the castings before they leave our Ductile Iron Foundry. For over 40 years we have checked and assured the nodularity in every ladle of Ductile Iron. We would like to be your ductile iron casting supplier. Come find out why so many companies come to us.

Learn More About Willman Industry’s Ductile Iron Castings and Grades

Austempered Ductile Iron (ADI) Casting:

Austempering is primarily used to improve strength and toughness of Ductile Iron. It can also reduce or eliminate its distortion. Varying Austempering treatments will result in varying properties. Because we know the quality of the raw materials before they enter the furnace and the metallurgy occurring within the furnace; we are able to assure the proper microstructure of the iron before heat treating is applied to the iron to produce ADI. Our commitment to every step of the process produces superior castings.

Austempering is primarily used to improve strength and toughness of Ductile Iron. It can also reduce or eliminate its distortion. Varying Austempering treatments will result in varying properties. Because we know the quality of the raw materials before they enter the furnace and the metallurgy occurring within the furnace; we are able to assure the proper microstructure of the iron before heat treating is applied to the iron to produce ADI. Our commitment to every step of the process produces superior castings.

Click here for specific application data regarding Austempered Ductile Iron produced at Willman Industries.

In the case of lower tensile strength or elongation requirements, Willman Industries can use grey iron instead of ductile iron for your iron castings.

At Willman Industries ABS Certified Foundry we meet and, in almost every case, exceed our customer’s specifications. It is our commitment to quality that will prove you don’t need to go anywhere else.

Solution Strengthened Ductile Iron:

In general with Solution Strengthened Ductile Iron improved machinability properties will be found for these castings as a result of lower than average and a more homogeneous hardness. Tool wear will decrease resulting in an improved tool life, or; productivity could be increased because of the ability to increase the cutting speeds. Adaptations to the quality of your tooling may be necessary as the chips from Solution Strengthened Ductile Iron will not as easily break when compared to Ductile Iron. Normally Solution Strengthened Ductile Iron surfaces will be smoother with a reduction in the variations of machined tolerances. These improvements occur not only within each casting but form each batch to batch as the Solution Strengthened properties are more consistent.

Click Here to Learn More About Willman Industries Solution Strengthened Ductile Iron Grades.