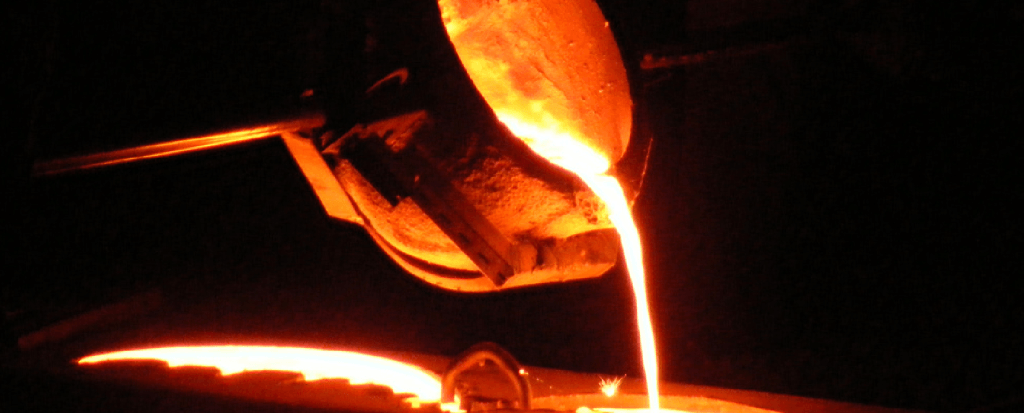

Iron Casting is the Core of Willman Industries

Iron Casting is the Core of Willman Industries

Willman Industries iron castings have been used by American manufacturers for over a hundred years. Serving the industry since 1912, we have the knowledge and experience most companies need to save them money while providing high quality castings. While many iron casting foundries have been closing their doors over the first two decades of the 21st century, Willman continues to grow strong, with no losses and no debt.

We specialize in the most common kind of iron castings, especially grey iron castings and ductile iron castings. You will find our iron castings in places like mines, oilfields, heavy-machinery, and all sorts of transportation. Why are Willman iron castings so popular? Sometimes you can save more than 50% casting a part instead of fabricating it, and casting iron will ensure the precision you need, which cannot always be promised with fabrications. The general rule is the more complicated the piece, the more you will save by having your part cast.

Not All Iron Is Equal

The oldest type of iron casting at Willman Industries is gray iron. Coming in nineteen different grades, gray iron is used in many different places from manufacturing to shipping. It is the ideal choice for application requiring moderate strength and excellent vibration dampening. For more information about gray iron, CLICK HERE.

In the mid-20th century the newer ductile iron grades were developed. The twenty different grades of the less expensive iron were sought for their higher strength and greater ability to withstand stress. The more ductile iron has shown its superiority in a variety of applications, including engine casings, control arms, hubs, and flywheels. You can find more information regarding ductile iron HERE.

In the mid-20th century the newer ductile iron grades were developed. The twenty different grades of the less expensive iron were sought for their higher strength and greater ability to withstand stress. The more ductile iron has shown its superiority in a variety of applications, including engine casings, control arms, hubs, and flywheels. You can find more information regarding ductile iron HERE.

The large number of grades with which we have experience allows us to be able to provide the cast parts you want with the highest quality and reliability in the industry. We are proud to be a precision iron casting manufacturer.

The Best Quality at the Right Price

Do you have a part you think might be a candidate to become an iron casting? Just give us a call and our engineering team can work with you to design your part as an iron casting. We ensure the part meets your form, fit, and function requirements plus we help you engineer the part to be as inexpensive to cast as possible while reducing or eliminating any machining.

We can also help specify the material and the process that would best suit your part, whether you need something that is impact resistant, has an extremely long wear life, or needs high tensile strength, we can tell you what will be the optimal material and process for your iron casting.

One of the secrets to a well-designed casting is a well-designed mold. Where to put things like the gates and vents can dramatically affect the cost, quality, and aesthetics of your parts. Since all we do is iron castings, we already know how to best design molds for your parts and even what type of molds to use (like green sand or no-bake casting molds).

We Have the Grade of Iron You Need

Some of the Willman Industries iron castings grades include:

Grey Cast Iron

- 20,000B – 55,000B

- All Meehanite Cast Iron Grades

- Learn more about our Grey Iron Casting Capabilities

Ductile Iron

- Ferritic Ductile Iron

- Pearlitic Ductile Iron

- High Strength Pearlitic Ductile Iron

- High Silicon Molybdenum Ductile Iron

- Austempered Ductile Iron

- All Meehanite Ductile Iron Grades

- Learn more about our Ductile Iron Casting Capabilities

What Are You Waiting For?

Call us today for a free consultation or to schedule a tour of our facilities. Willman produces most of the commonly used grades of gray iron and ductile iron. Send us the drawings and specifications of your latest project today and we will provide timely feedback and/or quotations. Once you see our drive for quality and excellence you will know that we are the right fit for your part manufacturing!