Many Foundries, One Roof

Willman Industries high-performance, high-integrity castings are found in the finest products of many of the most demanding and respected companies in the world. Willman Industries is one iron foundry among many, but not all foundries are made the same nor can one foundry economically cast every part. That is why Willman has grown to be many foundries under one roof. It is our commitment to providing the best services possible for our customers that has driven our expansions and improvements! Below is a comprehensive list of the different foundries that you will find under our roof, providing variety in material and process, with a unifying dedication to quality control that makes us the best in the business!

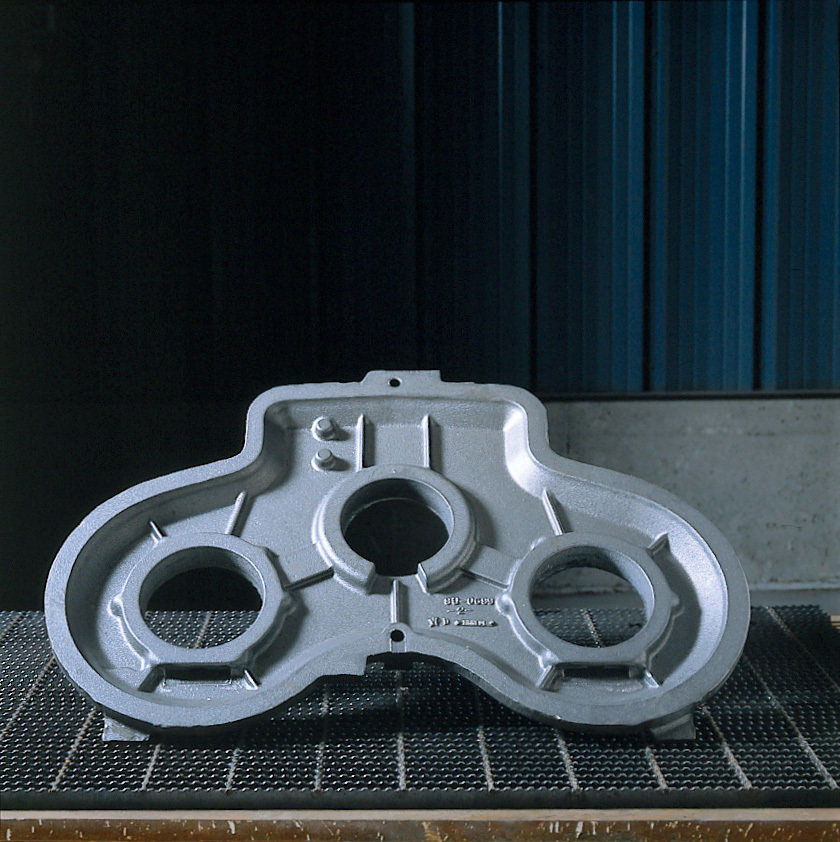

Grey Iron Foundry

Find out more about our Grey Iron Foundry.

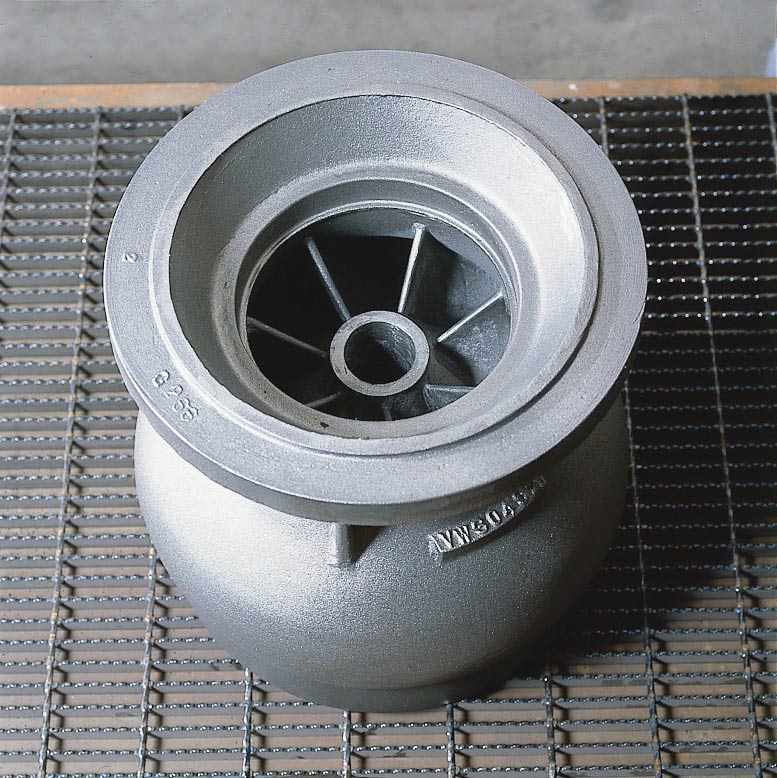

Ductile Iron Foundry

We were the second foundry in the United States to produce ductile iron. For over 40 years we have maintained this commitment for our ductile iron foundry and we are going to continue it for many more. When you need a high-performance and tight-tolerance casting, ductile iron outperforms steel in many applications. This makes it the prime choice for use for crankshafts and axles. As always, we are committed to the highest quality for all that we produce! Casting ductile iron is just another day’s work at Willman where we are used to producing high-performance castings on a daily basis.

Find out more about our Ductile Iron Foundry.

Green Sand Foundry

Green Sand Casting is the most common form of casting in the US. Most high volume parts are cast using green sand molds. As the leading green sand foundry in the United States, we are the obvious choice for your product. Our equipment allows for a broad spectrum of shapes and sizes to be cast in high volumes using the green sand process at an economical price. Our experience allows us to leverage green sand casting to your best advantage.

Find out more about our Green Sand Foundry.

No-Bake Foundry

No-Bake Casting is the second most common form of casting in the US. The process is best for larger parts that are too big for making green sand molds. Willman Industries has the equipment and experience to make no-bake castings from 500 lbs up to an incredible 40,000 lbs. Our facilities can handle your production schedule whether you need one casting a year or a dozen per day.

Find out more about our No-Bake Foundry.

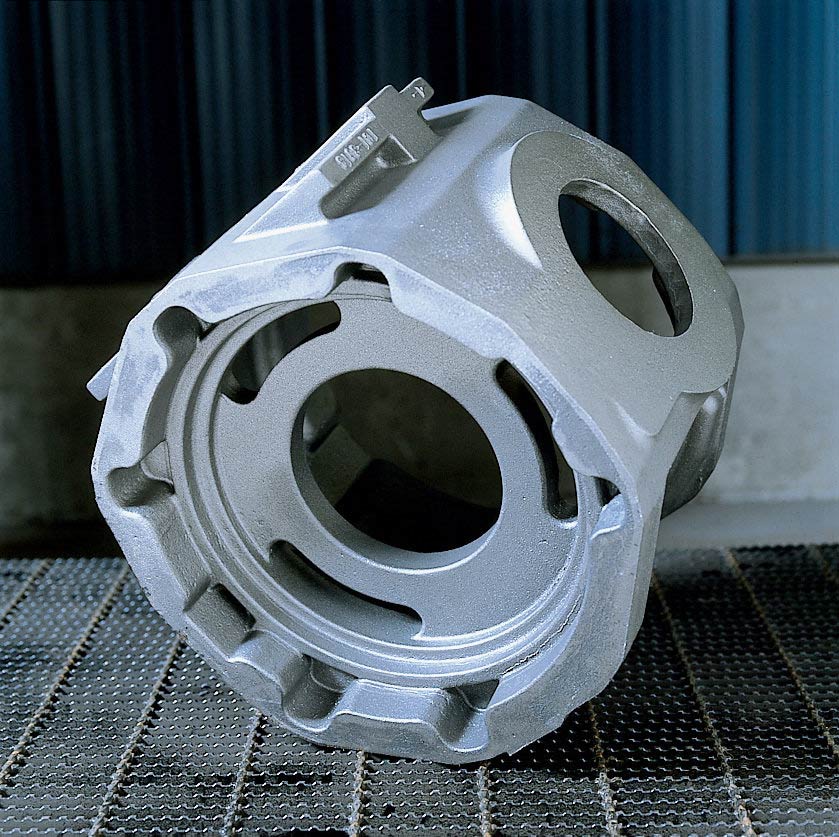

Meehanite Foundry

Meehanite is a proven process of how to make precision high-performance parts that has been around since 1931. With Willman’s decades-old relationship with Meehanite Metal Corp. (the Meehanite certifying organization), Willman Industries has the experience to easily make Meehanite and Meehanite like castings. This gives you the strongest and most durable product possible. We carefully control every aspect of production, from the materials used to the way they are cast for your part. We are fully certified and approved.

Read more about our Meehanite Castings!

ISO 9000 Certified Foundry

Willman is an ISO 9001:2015 certified foundry, letting you know we have a documented Quality Management System (QMS) that is audited by a third party, and which is focused on continuous improvement. We feel that this certification is an important way for us to show our customers our commitment to their needs. Why chance your cast parts with a foundry that cannot promise consistent product that meets your specifications every time?

See our full list of certifications and awards here.

ABS Certified Foundry

Like ISO certification, the American Bureau of Shipping or ABS Certification is a shortcut for you to know we are committed to delivering you high-quality castings every time we deliver. Throughout their history, this organization has worked tirelessly to ensure the quality of products and services being provided in the United States. We are proud to bear their certification as a testament to the quality parts we have produced for our entire history.