Grey Iron Casting at Willman Industries

At Willman, we work with a variety of different metals to produce the parts that you need. Each one (and the different combinations thereof) have unique qualities that lend themselves to very different applications. One of our primary metal types for metal castings is grey cast iron.

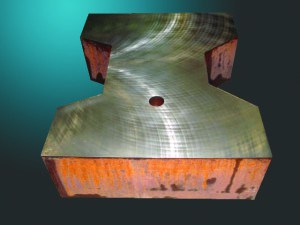

Grey iron castings are the most common type of cast iron that is poured today. Due to its graphitic microstructure, it forms grey fractures, hence the name grey cast iron or simply grey iron. The color ultimately is due to a combination of the material used and the heating/cooling process used to harden it. As with all things, grey iron is only as good as the materials that are used to make it. Willman Industries only buys the best scrap and raw materials to produce our grey iron castings. We believe this is the key to our superior grey iron castings.

The graphite level in grey iron is a very critical property that makes it a common engineering alloy. The graphite acts as a lubricant when machining the casting by either cutting or boring. The graphite flakes also lubricate when the casting is in use which assists in reducing wear on parts as well it absorbs energy due to its dampening capabilities. We are able to control the metallurgy in the furnace, and in each ladle to ensure that your grey iron casting has the graphitic properties to suit your needs.

Although grey iron castings have low tensile strength and poor ductility, its high thermal conductivity and specific heat capacity make it a very valuable metal to cast. It is used in a wide variety of industries and functions, including parts for engines, plows, vehicle suspensions, machinery bases, turbine castings, and pumps. Its ability to dampen vibrations makes it perfect for applications such as machine bases and turbine housings. The capability to withstand extreme thermal cycling lends it to use for engine cylinder blocks, valves, and disc brake rotors. Since it is the cheapest type of iron to produce it is also preferred for weights and counter-weights.

We Go the Extra Mile

We Go the Extra Mile

Our grey iron foundry follows the Meehanite process for wedge control on all of our grey iron castings. The dense microstructure of Meehanite metal assures casting solidity and consistent physical properties. Since its development in the 1920s, this process has found an excellent use for items such as machine tools, cylinder heads, and gears.

At Willman Industries we have engineered our own gating and rigging to ensure the quality and consistency of the entire pour process. Maintaining appropriate levels of silicon helps to increase the fluidity of the pour as well as promotes corrosion resistance of the completed casting.

Willman’s grey iron foundry will meet and, in almost every case, exceed our customer’s specifications.