Harry Brearley: Pioneering Innovation in the Iron Foundry and Steel Industry

Harry Brearley and Iron Foundry and Steel Innovation

Harry Brearley was an English metallurgist who is best known for his groundbreaking work on stainless steel. In the early 20th century, the steel industry was rapidly expanding, and there was a growing demand for steel that was resistant to corrosion and rust. Brearley’s innovative work in the field of metallurgy paved the way for the development of stainless steel, a material that has had a profound impact on the modern world.

An Early Start in Steel

Brearley was born in Sheffield, England, in 1871. He began his career as an apprentice at a local steelworks and quickly developed a passion for metallurgy. In the early 1900s, he was hired by a steelworks in Sheffield to research the properties of steel and investigate new methods for improving its strength and durability.

Brearley was born in Sheffield, England, in 1871. He began his career as an apprentice at a local steelworks and quickly developed a passion for metallurgy. In the early 1900s, he was hired by a steelworks in Sheffield to research the properties of steel and investigate new methods for improving its strength and durability.At the time, iron foundries were the primary source of steel production. Foundries used a process known as the Bessemer process, which involved blowing air through molten iron to remove impurities and produce steel. While this process was effective, it had limitations. The resulting steel was prone to corrosion and rust, which made it unsuitable for many applications.

Recognizing the Need for Innovation

Brearley recognized the need for a new type of steel that was resistant to corrosion and rust. He began experimenting with different alloys and discovered that adding chromium to steel improved its corrosion resistance. He called this new material “rustless steel,” which later became known as stainless steel.

Brearley’s discovery was a significant innovation in the steel industry. Stainless steel has a wide range of applications, from kitchen appliances to medical devices. Its resistance to corrosion and rust makes it an ideal material for use in harsh environments, such as marine and chemical processing applications.

Other Innovations in the Iron Foundry Industry

Brearley’s work on stainless steel was just one of many innovations in the steel industry during the early 20th century. Iron foundries were constantly searching for new methods for improving the quality of steel and increasing production efficiency. One notable innovation was the introduction of the electric arc furnace.

The electric arc furnace was developed in the late 19th century but was not widely used until the early 20th century. The furnace uses an electric arc to melt scrap steel and other materials, which are then transformed into new steel products. This process is more efficient than the Bessemer process and can produce steel of higher quality.

The electric arc furnace was developed in the late 19th century but was not widely used until the early 20th century. The furnace uses an electric arc to melt scrap steel and other materials, which are then transformed into new steel products. This process is more efficient than the Bessemer process and can produce steel of higher quality.Improvements in Casting

Another innovation in the steel industry was the development of continuous casting. Continuous casting involves pouring molten steel into a mold that moves continuously through the production process. This method allows for the production of steel in a continuous stream, which is more efficient than traditional batch methods.

In addition to these innovations, the steel industry also made significant advances in automation and production efficiency. Iron foundries began using automated machinery to reduce labor costs and increase production output. This allowed for the production of steel on a larger scale and at a lower cost, making it more accessible to consumers.

The Modernization of the Iron and Steel Industries

The modernization of the steel industry during the early 20th century had a profound impact on the global economy. The availability of high-quality, affordable steel fueled the growth of numerous industries, from construction to transportation. The development of stainless steel in particular opened up new possibilities for product design and engineering.

Today, the steel industry continues to evolve and innovate. New technologies, such as 3D printing and nanotechnology, are being applied to steel production to create even stronger and more durable materials. The industry is also exploring ways to reduce its environmental impact and improve sustainability.

New Materials and New Technologies

Harry Brearley’s work on stainless steel was a significant innovation in the steel industry. His discovery paved the way for the development of a material that has had a profound impact on the modern world. The innovations in the steel industry during the early 20th century demonstrated the importance of continuous research and development in the metallurgy field. Iron foundries had to constantly experiment with different alloys, production methods, and machinery to remain competitive and meet the growing demand for steel.

The emphasis on innovation and technological advancement is still a driving force in the steel industry today. In addition to developing new steel alloys and production methods, the industry is also exploring ways to improve sustainability and reduce its carbon footprint. This includes the use of renewable energy sources, such as wind and solar power, and the implementation of more efficient production processes.

Transforming the Global Economy

Innovation is also important for the steel industry to remain relevant and competitive in a rapidly changing global economy. Steel production has become increasingly automated, with many foundries utilizing robotics and artificial intelligence to streamline operations and increase efficiency. Additionally, the rise of electric vehicles and renewable energy infrastructure has created new opportunities for steel producers to develop specialized products that meet the specific needs of these industries.

The importance of innovation in the steel industry extends beyond just product development and production efficiency. It also plays a crucial role in driving economic growth and creating jobs. Steel production is a major contributor to many national and regional economies, and continued innovation in the industry can help to create new jobs and support economic development.

Harry Brearley’s work on stainless steel was just one of many innovations in the steel industry during the early 20th century. The industry had to constantly experiment with new alloys, production methods, and machinery to remain competitive and meet the growing demand for steel. Today, the steel industry continues to innovate and evolve, with a focus on developing new products, improving efficiency, and reducing environmental impact. The importance of innovation in the steel industry extends beyond just product development and production efficiency, it also plays a crucial role in driving economic growth and creating jobs.

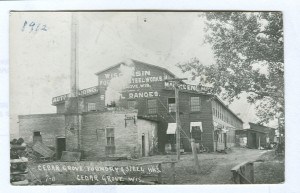

Willman and Innovation

In conclusion, the steel industry has a long history of innovation and continues to be a driving force in the global economy. From the development of stainless steel to the use of AI and machine learning in production processes, innovation has been essential to the industry’s growth and success. The steel industry will continue to evolve and innovate, driven by changes in technology, industry trends, and consumer demand. As the industry continues to innovate, it will play a critical role in supporting economic growth and sustainability for years to come.

In conclusion, the steel industry has a long history of innovation and continues to be a driving force in the global economy. From the development of stainless steel to the use of AI and machine learning in production processes, innovation has been essential to the industry’s growth and success. The steel industry will continue to evolve and innovate, driven by changes in technology, industry trends, and consumer demand. As the industry continues to innovate, it will play a critical role in supporting economic growth and sustainability for years to come.Willman is proud of these innovators in the iron and steel industry. Without their contributions to these important industries, we would not have some of the things that we take for granted today. Our engineers, specialists, and technicians are inspired by their ingenuity and motivated to build on their success.

Call us today to find out how our dedication to excellence can benefit your company and your customers. Our knowledgeable staff and state-of-the-art facilities will provide the quality that you deserve!