Spheroidal graphite cast iron is a fancy way of saying “ductile iron.” For a full description of this material, you can visit our “What is ductile iron” page. These castings are also known as S.G. iron castings or just S.G. iron.

The fancy name “spheroidal graphite cast iron” comes from the make-up of ductile iron. We are primarily dealing with iron that is cast in a foundry (obvious, right?). One of the primary ingredients added to the iron is graphite(or carbon) in order to make it stronger. Ductile iron contains 3.2-3.6% carbon.

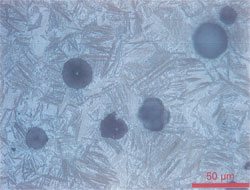

Now, other cast irons also contain graphite. It is the round tube shape of the carbon that adds the important “spherical” to the name making ductile iron one of the most popular irons to pour in a foundry.

If the carbon is not “directed” into a specific shape, the carbon ends up as flakes in the metal. These flakes look like squiggly lines if you look at a cross-section of gray cast iron at 100x magnification. This flake structure of the carbon makes the metal brittle and prone to cracking. Yet, by adding additional ingredients and controlling the casting process, you end up with spheres of graphite that adds strength and reduces brittleness.

Spherical graphite iron castings (ductile iron castings) are very strong compared to regular cast iron (gray iron). The tensile strength of cast iron is 20,000 – 60,000 psi while ductile iron starts at 60,000 psi and can go to 120,000 psi. The yield strength for ductile iron is generally 40,000 – 90,000 psi but the yield strength of cast iron is so low it is considered not measurable.

Most of the magic in making spherical graphite cast iron happens in the furnace with the molten iron. You start with the iron (of course) and then add more carbon than the iron would normally be able to absorb into the structure. Explaining the iron-carbon relationship in another way, it is like adding so much salt to your water that you reach a point no more salt will dissolve. Silicon, Sulphur, manganese, and oxygen all do their part in the mix to help the carbon to form into spherical graphite structures as the iron cools. This, admittedly, is an oversimplification of the process.

Again, if you want additional information, feel free to swing on over to our page on ductile iron.