A Short History of the Iron Foundry in America: The Gilded Age

The Iron Foundry and the Gilded Age

The iron foundry industry moved into a time of extensive expansion as iron was introduced into the growing construction and transportation industries. What came to be called the “Gilded Age” of American history was a time of reconstruction of the war-ravaged East and exploration of the frontiers of the West. Literally undergirding the building and rebuilding were the iron columns, girders, and rails produced in the foundries from Pennsylvania to Wisconsin.

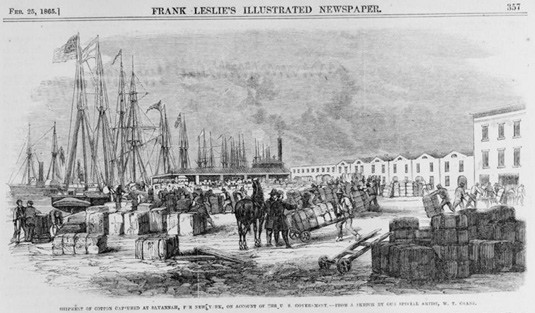

Assessing the Cost of the Civil War

The Civil War was devastating for the United States. It is still the deadliest war in American history, claiming over 620,000 lives. That is more than World War I and World War II combined. Most large cities in the southern United States had lost 30% or more of their buildings and most of their manufacturing infrastructure. Rail lines in the South were decimated and essentially useless. The North didn’t avoid the damage of the Southern war machine altogether, but its losses were far from the industrial and commercial centers. Nevertheless, the reconstruction of the southern states required much capital and concentration of resources.

The Civil War was devastating for the United States. It is still the deadliest war in American history, claiming over 620,000 lives. That is more than World War I and World War II combined. Most large cities in the southern United States had lost 30% or more of their buildings and most of their manufacturing infrastructure. Rail lines in the South were decimated and essentially useless. The North didn’t avoid the damage of the Southern war machine altogether, but its losses were far from the industrial and commercial centers. Nevertheless, the reconstruction of the southern states required much capital and concentration of resources.

The North was ready for the economic challenge that the end of the war brought. Prior to the war, the industrial North was frustrated by the hesitation of the agricultural South to policies that would be financially beneficial to them. The southern politicians withheld their crucial support in an attempt to draw concessions from the northern states. The situation had created political gridlock in Washington. With the Southern states now seceding, the northern politicians were free to enact the plans they had wanted for several years. In 1861, Congress passed one of the first of these bills.

An Economic Approach to the Conflict

The Morrill Tariff Act had been a point of contention between the two sides throughout 1860 and the passing of that bill was a plank of the Republican party platform for that election. It was on the strength of his support of the tariff that Lincoln won the vote in Pennsylvania and New Jersey. The tariff was disliked by both the South and England due to the lucrative cotton trade between the two. Within a month of the organization of the Confederate States of America, the Morrill Tariff Act was passed by the newly-unfettered Senate. Due to the anticipated costs of the new war, a second tariff bill was introduced by Rep. Justin Morrill later the same year and passed hastily. These acts brought the United States to equal tariff levels to the European countries.

The Morrill Tariff Act had been a point of contention between the two sides throughout 1860 and the passing of that bill was a plank of the Republican party platform for that election. It was on the strength of his support of the tariff that Lincoln won the vote in Pennsylvania and New Jersey. The tariff was disliked by both the South and England due to the lucrative cotton trade between the two. Within a month of the organization of the Confederate States of America, the Morrill Tariff Act was passed by the newly-unfettered Senate. Due to the anticipated costs of the new war, a second tariff bill was introduced by Rep. Justin Morrill later the same year and passed hastily. These acts brought the United States to equal tariff levels to the European countries.

In addition to the tariffs, Congress sought to unite the western states and territories with the North. The first proposal had been made by Dr. Hartwell Carver, who in 1847 had suggested a route that would connect Lake Michigan to the Pacific Ocean. He was able to secure a congressional charter and proceeded to conduct surveys to determine the best route. Soon his vision would be taken up by a variety of investors and businessmen. The Transcontinental Railroad would not only spur the settlement of the West, but it would be an economic boom for the iron foundries and many other industries.

In addition to the tariffs, Congress sought to unite the western states and territories with the North. The first proposal had been made by Dr. Hartwell Carver, who in 1847 had suggested a route that would connect Lake Michigan to the Pacific Ocean. He was able to secure a congressional charter and proceeded to conduct surveys to determine the best route. Soon his vision would be taken up by a variety of investors and businessmen. The Transcontinental Railroad would not only spur the settlement of the West, but it would be an economic boom for the iron foundries and many other industries.

When the war ended the arrangements that had been made to fund the war now became the lifeline needed to fund the reconstruction. Businessmen in both the North and the South saw new opportunities in the chaos that personified the southern cities in those chaotic few years. As structure finally began to be realized in the war-torn South, a fresh economic revitalization flowed through the nation. Part of that revitalization was in the literal reconstruction of the office buildings, mills, factories, and railroads that had been destroyed during the war. With new buildings came the new building materials and processes. Iron foundry production kicked into high gear and raced to keep up with the unrelenting demand for their products.

The Spread of American Iron Foundries

Iron foundries spread across the United States, following the new iron veins that were discovered in Michigan, Wisconsin, and Minnesota. The iron was brought to the foundries via the Great Lakes and processed there. The number of iron foundries exploded, taking iron production with it. Every year there were gains, racing against Great Britain for supremacy. Between the years 1885-1890 the United States iron industry more than doubled its production. The US production of 9.2 million gross tons bested Great Britain’s 7.9 million gross tons. By 1910, American iron production had exceeded 24 million gross tons. Foundries came and went, many not surviving the latest boom-to-bust cycle in the US economy.

exceeded 24 million gross tons. Foundries came and went, many not surviving the latest boom-to-bust cycle in the US economy.

But the iron industry, for all of its problems, was an integral part of the United States economy. Iron and steel were literally everywhere. The new bridges crossing gaps and rivers, the buildings rising out of the cities, the locomotives charging across the new tracks that were being laid down, and the steamships that were crossing the oceans all replied on the iron foundries to produce. Even the steam engines in those trains and ships required the parts and boilerplates that were poured out for those crucibles.

Dutch Immigration Brings Industry and Innovation

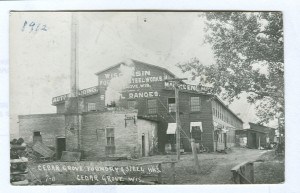

It was into this world that the iron foundry in our little town of Cedar Grove, Wisconsin. Sitting along the beautiful shores of Lake Michigan and along the Chicago & Northwestern railway line, Cedar Grove was well-positioned to support an iron foundry. The earliest records of a foundry existing date to just before the turn of the 20th century. In those early years, it produced a hodge-podge of products, from pots and pans to bicycle parts. By 1899, the foundry established itself as the Wisconsin Foundry and Steel Works. Their product line had transitioned to kitchen stoves, wagons, and auto jacks. The generations of the descendants of the immigrants that settled there brought the industriousness of their Dutch heritage to bear.

It was into this world that the iron foundry in our little town of Cedar Grove, Wisconsin. Sitting along the beautiful shores of Lake Michigan and along the Chicago & Northwestern railway line, Cedar Grove was well-positioned to support an iron foundry. The earliest records of a foundry existing date to just before the turn of the 20th century. In those early years, it produced a hodge-podge of products, from pots and pans to bicycle parts. By 1899, the foundry established itself as the Wisconsin Foundry and Steel Works. Their product line had transitioned to kitchen stoves, wagons, and auto jacks. The generations of the descendants of the immigrants that settled there brought the industriousness of their Dutch heritage to bear.

Those early years brought both prosperity and tragedy. Many of the folks who settled the area around Cedar Grove were immigrants from the overcrowded and economically depressed Netherlands. They brought with them knowledge from a variety of different industries and immediately began using those skills to establish businesses. Tailors, shoemakers, blacksmiths, furniture builders, teachers, and pastors all came ashore to fill in the little towns around Cedar Grove. A mill was built and a farmers cooperative was established. Some who sought out the potential of the new frontier lands never made it. The journey was long and hard. One ship bringing immigrants even caught fire off the shore not far from our town. Of the 200 immigrant hopefuls, only 25 made it off the ship alive.

Those early years brought both prosperity and tragedy. Many of the folks who settled the area around Cedar Grove were immigrants from the overcrowded and economically depressed Netherlands. They brought with them knowledge from a variety of different industries and immediately began using those skills to establish businesses. Tailors, shoemakers, blacksmiths, furniture builders, teachers, and pastors all came ashore to fill in the little towns around Cedar Grove. A mill was built and a farmers cooperative was established. Some who sought out the potential of the new frontier lands never made it. The journey was long and hard. One ship bringing immigrants even caught fire off the shore not far from our town. Of the 200 immigrant hopefuls, only 25 made it off the ship alive.

Those arduous journeys strengthened the resolve of those Dutch immigrants to make a place for themselves in the New World. With grit and determination, they built their towns and farms and churches and schools. Their businesses thrived not from chance, but because of their drive to succeed in their new home. That meant innovation…finding new and better ways to do what needed to be done.

Our Heritage is Your Benefit

Our heritage of innovation and determination is what established our foundry. The generations of families that have worked in and around our foundry have made it what it is today. Our employees are the best in the business, dedicated to producing the best parts in the industry. We are profoundly aware that the history we are making today is the heritage that our children and grandchildren will build upon.

Choose Quality, Choose Willman

Let us use that rich heritage and legacy-building determination to your benefit. Call us today and schedule a tour of our state-of-the-art facilities. Watch our dedication to our craft and the innovation of our engineers as we work diligently for our customers. Then sit down with our planners and discuss the parts you need and the quality we can provide. Choose quality, choose Willman.