The Rise of the Early Republic Iron Foundry

In the late 1700s, a man named Benjamin Longstreth settled along the French Creek near the little village of Manavon. He renovated an old grist mill and added a small dam across the creek to establish a foundry there In 1790 he officially opened the French Creek Nail Works for business. As the first nail factory in the United States, it became the largest producer of nails in the country. As the company flourished, so did the area around it. Settlers funneled up the Schuylkill River valley toward the growing city of Reading. Slowly the area was settled, requiring better roads and bridges.

Twenty-three years later Louis Wernwag moved to the area. He was making a name for himself building remarkable bridges throughout southeast Pennsylvania. He had just completed building the longest wooden bridge span ever recorded to that time over the Schuylkill River in Philadelphia. The French Creek factory had gotten his attention and he made the owners an offer. In 1813 he became the owner of the nail factory and renamed it the Phoenix Iron Works. He immediately went to work to innovate nail production. It was there that he invented a spike cutting machine. He followed that with improvements and additions to other plant machinery. He also began experimenting with anthracite coal, which was considered at the time difficult to use. His experiments worked out well for the factory, which increased its production of highly sought-after nails.

A Company Town Is Born

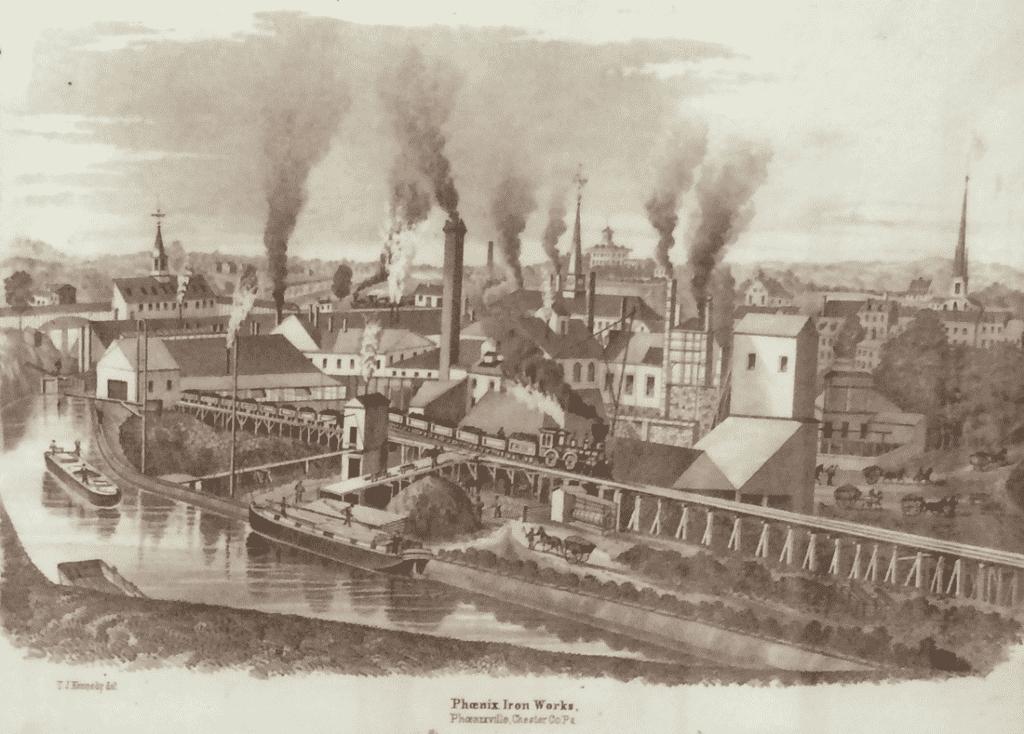

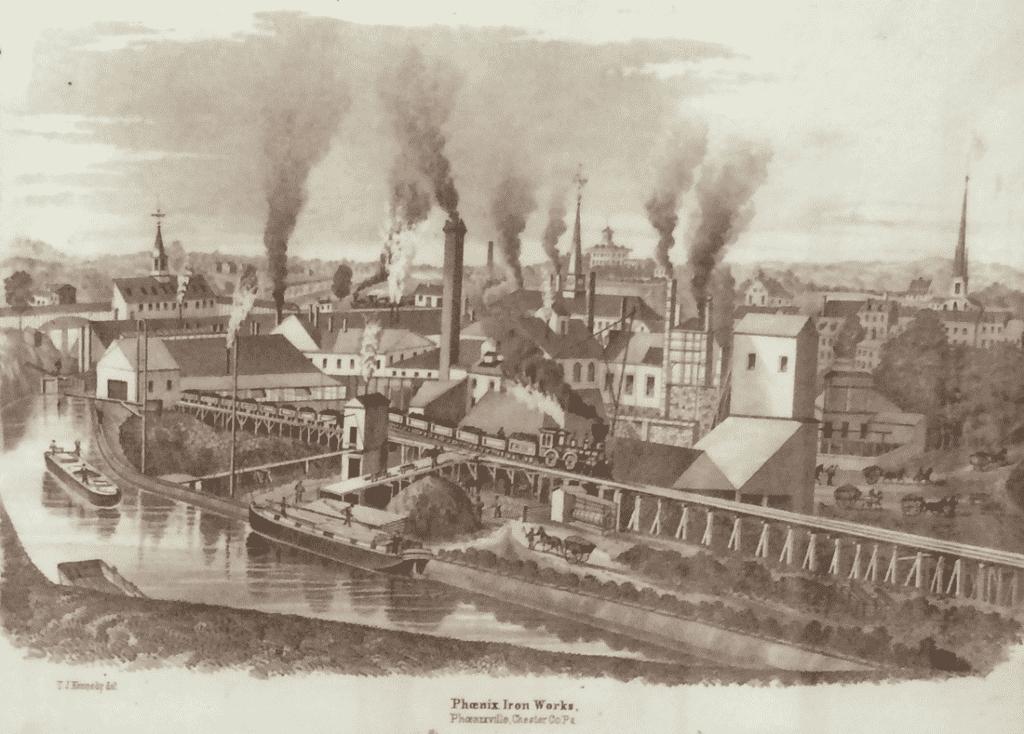

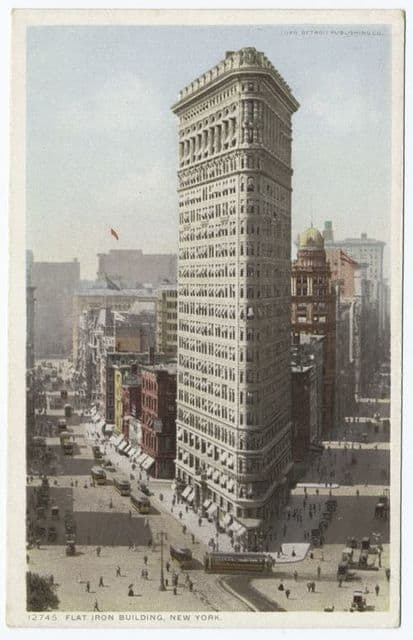

Phoenix Iron Foundry (circa 1860)

Wernwag brought needed leadership to the area and soon recognized the need for the village that grew up around the factory to become its own borough. The new borough was established in 1827 and its name was Phoenixville. Many Irish immigrants would arrive in the 1830s to work at the growing iron foundry. By 1840 the town had 809 residents, but that number would grow to over 3,300 people in just eight years! Such an explosion in growth was primarily due to the expansion of the iron foundry. At the same time he was reorganizing and expanding the town, Wernwag was also expanding the company. He knew that the company was going to need to continue expanding to survive, so in 1827 he brought in two sets of brothers to add capital investment for the expansions. He semi-retired to his lumberyards in Maryland and allowed the business-savvy Reeves Brothers to take over the business.

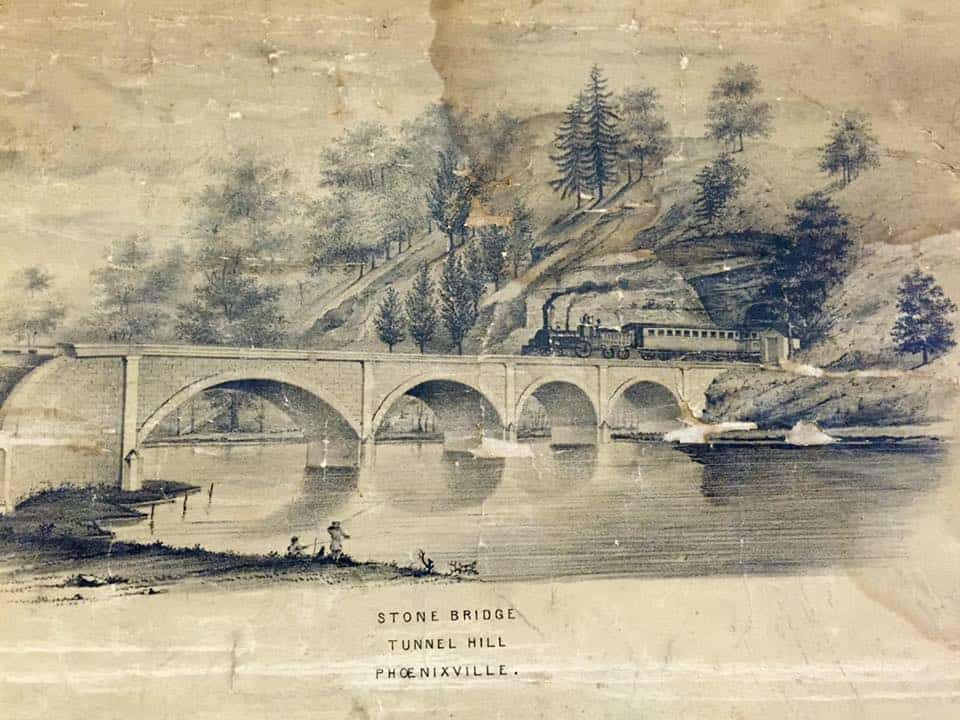

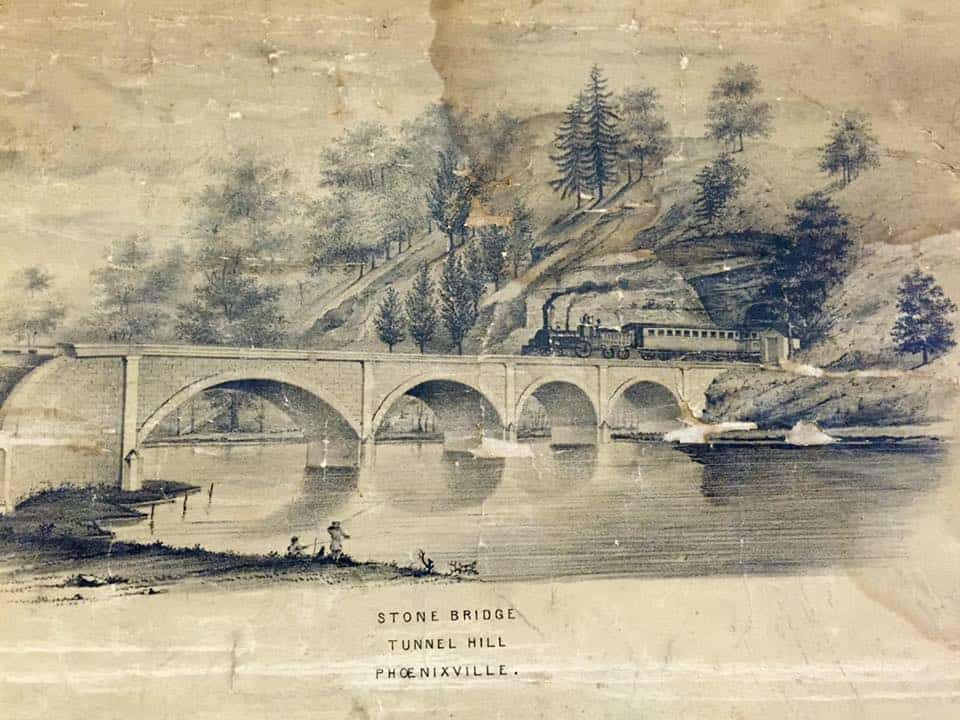

The Reeves Brothers had a knack for business, especially the iron foundry business. When they took over the ownership of Phoenixville, the area had just gained access to large coal reserves via the Schuylkill Navigation Canal. When it opened in 1825, Phoenixville was able to ship in coal directly to its mill. This shipping method served them well until the railroad lines opened between the foundry and its supply of anthracite coal in Pottsville, PA in 1842. The railroad could deliver larger amounts of the coal faster than the old barges, giving them a distinct advantage.

Iron Foundries and Railroad Lines

In the 1840s the demand for rails and spikes grew exponentially as railroads expanded across the United States. This was especially true in Pennsylvania as the rail lines in that state more than tripled in the 1840s and 1850s. In 1841 the Phoenixville iron foundry added six more puddling foundries, increasing their production potential well past every other foundry in the area. The next year a survey of the company’s production facilities recorded that the blast furnace and refining furnace could both produce 1,500 tons of iron each per year. The same report noted that the rolling mill was capable of converting all of that into bars per year. The mill was employing over 140 people at that time, but that number was about to expand considerably.

Illustration of the Phoenix Iron Works by T.J. Kennedy in 1860 – https://civilwartalk.com/threads/history-of-the-phoenix-iron-works.166302/

As the foundry expanded its facilities in Phoenixville it also opened other foundries and mills in the region. Its products continued to diversify, moving well beyond the nails that had established the foundry as a hotbed of innovation. Soon they were producing rails for the railroad, cannons for the army, and columns for the construction companies. In fact, the horizons were so full of possibilities that the loss of what got them started hardly slowed them down. On June 25, 1848, a fire started in the old nail factory. It represented the first substantial business and was the epicenter for the creation of the town. The building had been in almost continual use for over 60 years and had seen the village around it grow from a few families to thousands of people. By the end of the day it was gone and would never be rebuilt. The remainders of the old mill were hauled away and a state-of-the-art machine shop was built in its place.

Railroads Transform Pennsylvania

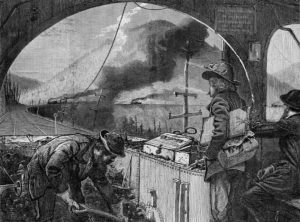

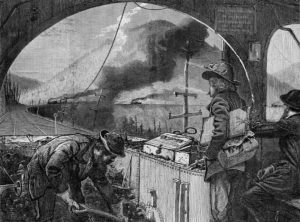

On the Way to Pittsburgh — Great Bend on the Alleghenies, 1871

The foundry at Phoenixville was not alone in the race to expand its business and modernize its facilities. Across the new United States foundries were pushing to be better, spreading out across what used to be frontier. Phoenixville rails soon took Pennsylvania’s trains across the Allegany Mountains to one of the first gateways to the West, the city of Pittsburgh. The arrival of the “iron horse” to that city transformed it from the shipbuilding titan that it was to the industrial capital that it became.

The period between 1820 and 1860 were critical to the expansion and development of the American iron industry. The innovations brought by the use of coal and coke as a fuel source drove the improvements in blast furnaces and puddling foundries. Iron foundries began to produce sufficient quantities of products that the United States no longer had to look elsewhere for any iron or steel products. The British blockades of the War of 1812 had the opposite of the desired effect, driving American independence from England’s industry instead of hobbling the young country.

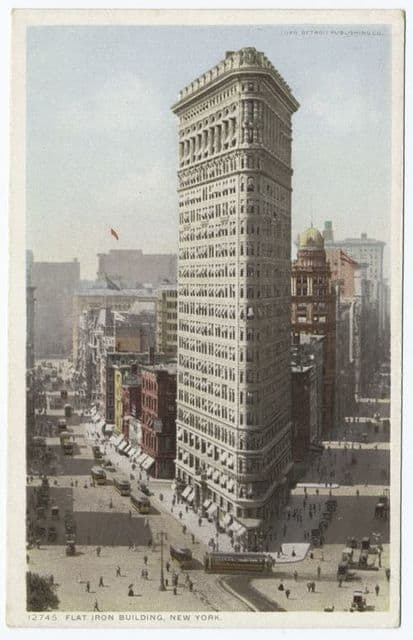

The First Glimpses of the Gilded Age

The steam engine inspired a host of industrialists and urban planners, preparing the American people for an industrial “Gilded Age”. The iron foundries produced the material for engine parts, rails, boilerplates, girders, posts, fittings, and so much more. Iron bridges began to replace the old wooden ones. Steel and iron became the supporting structures of public buildings and factories. The increase in wealth and economic power also drove the desire for increased military security. The United States government approached foundries like Phoenixville to provide them with artillery and other weapons. The majority of cannons used by the army came from Phoenixville and Pittsburgh.

As industry pushed further west, a deepening conflict was rising in the east. Congress was embroiled in conflict and tensions were at a breaking point. Compromises were attempted to ease those tensions. Politicians on both sides of the divide worked hard to avoid the inevitable conflict. Words were said that couldn’t be unsaid, things were done that couldn’t be undone. The divide became a chasm into which the United States fell. Brother took up arms against brother and the American Civil War began with the first shot of a cannon at Fort Sumner.

Iron Foundries Help Rebuild the Nation

Iron Foundries Help Rebuild the Nation

The rise of the industrialists and the expansion of the iron industry were initially hindered by the conflict. The years immediately after the war were also difficult. But the United States, now reunited, relied on the iron foundry industry as they rebuilt from the ruins of war. Our next installment will discuss the rise of the “Steel Belt” of the Gilded Age of American history. It is from that history that an iron foundry on the banks of Lake Michigan comes into being.

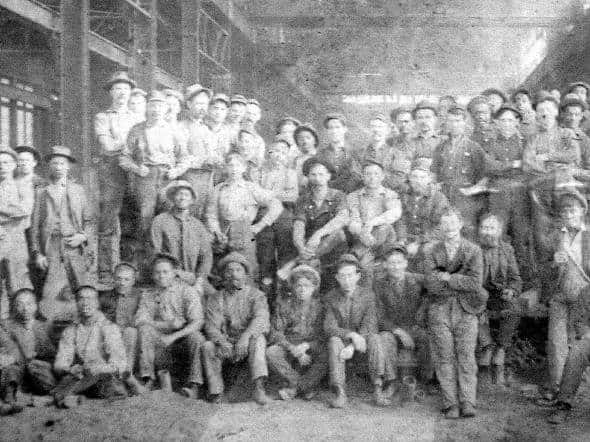

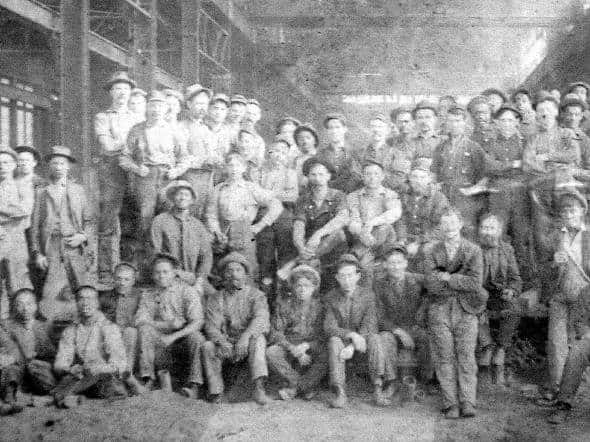

Our heritage of innovation and determination is what established our foundry. The generations of families that have worked in and around our foundry have made it what it is today. Our employees are the best in the business, dedicated to producing the best parts in the industry. We are profoundly aware that the history we are making today is the heritage that our children and grandchildren will build upon.

Choose Quality, Choose Willman

Let us use that rich heritage and legacy-building determination to your benefit.

Call us today and schedule a tour of our state-of-the-art facilities. Watch our dedication to our craft and the innovation of our engineers as we work diligently for our customers. Then sit down with our planners and discuss the parts you need and the quality we can provide. Choose quality, choose Willman.

The Reeves Brothers had a knack for business, especially the iron foundry business. When they took over the ownership of Phoenixville, the area had just gained access to large coal reserves via the Schuylkill Navigation Canal. When it opened in 1825, Phoenixville was able to ship in coal directly to its mill. This shipping method served them well until the railroad lines opened between the foundry and its supply of anthracite coal in Pottsville, PA in 1842. The railroad could deliver larger amounts of the coal faster than the old barges, giving them a distinct advantage.

The Reeves Brothers had a knack for business, especially the iron foundry business. When they took over the ownership of Phoenixville, the area had just gained access to large coal reserves via the Schuylkill Navigation Canal. When it opened in 1825, Phoenixville was able to ship in coal directly to its mill. This shipping method served them well until the railroad lines opened between the foundry and its supply of anthracite coal in Pottsville, PA in 1842. The railroad could deliver larger amounts of the coal faster than the old barges, giving them a distinct advantage.