Benjamin Huntsman: Bringing Needed Innovation for the Iron Foundry

Benjamin Huntsman and the Innovation of the Iron Foundry

Iron foundries have played a vital role in the industrial development of the world, and one name that stands out in the history of iron foundries is Benjamin Huntsman. A British inventor and manufacturer, Huntsman is credited with revolutionizing the production of steel and establishing the crucible steel process. His innovations paved the way for the growth of the iron foundry industry and the steel-making process, which led to the Industrial Revolution.

In this article, we’ll explore the history of iron foundries and their evolution over time, as well as the life and contributions of Benjamin Huntsman.

A History of Iron Foundries

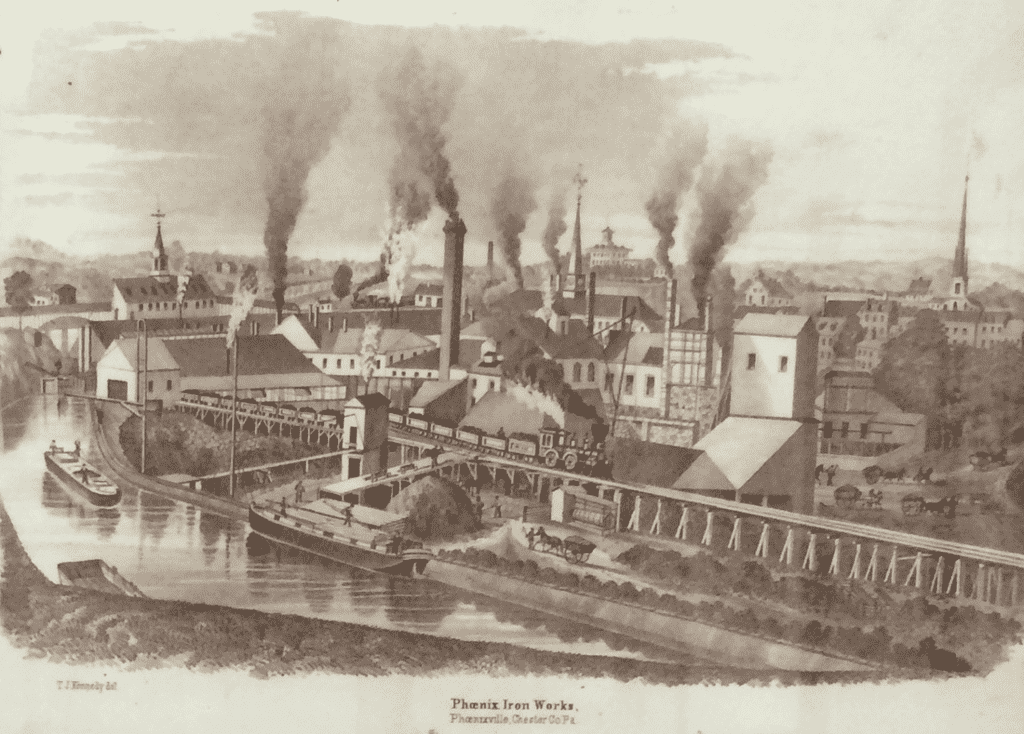

Iron foundries have been around for thousands of years. The first known iron foundry dates back to ancient China, where iron was used to create weapons, tools, and household items. However, it wasn’t until the Industrial Revolution that iron foundries became a major part of the global economy.

Iron foundries have been around for thousands of years. The first known iron foundry dates back to ancient China, where iron was used to create weapons, tools, and household items. However, it wasn’t until the Industrial Revolution that iron foundries became a major part of the global economy.During the Industrial Revolution, the demand for iron increased dramatically, as it was used to build bridges, railroads, and other infrastructure. The iron foundry industry grew rapidly, and new technologies were developed to make the process of producing iron faster and more efficient.

An Important Innovation

One of the major advancements in iron production was the Bessemer process, developed by Sir Henry Bessemer in the 1850s. This process involved blowing air through molten iron to remove impurities and create a purer form of iron. The Bessemer process revolutionized the iron industry, as it made the production of iron faster and more cost-effective.

Another significant innovation in iron production was the use of steel. Steel is a form of iron that contains carbon, and it is stronger and more durable than pure iron. The production of steel required a different process than the production of iron, and it wasn’t until Benjamin Huntsman’s development of the crucible steel process that steel production became practical.

Benjamin Huntsman and the Crucible Steel Process

Benjamin Huntsman was born in 1704 in Epworth, England. He was the son of a farmer, and he showed an early interest in science and engineering. Huntsman was particularly interested in the production of steel, and he began experimenting with different methods for making steel. At the time, the most common method for producing steel was the cementation process, which involved heating iron and charcoal in a sealed container for several days. This process produced a low-quality steel that was brittle and prone to breaking.

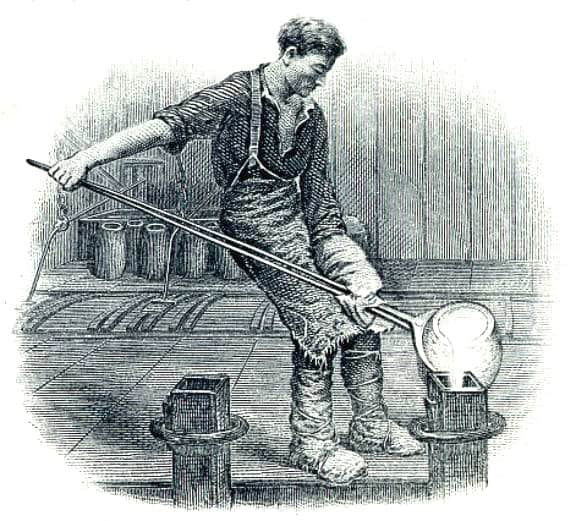

Benjamin Huntsman was born in 1704 in Epworth, England. He was the son of a farmer, and he showed an early interest in science and engineering. Huntsman was particularly interested in the production of steel, and he began experimenting with different methods for making steel. At the time, the most common method for producing steel was the cementation process, which involved heating iron and charcoal in a sealed container for several days. This process produced a low-quality steel that was brittle and prone to breaking.Huntsman believed that there was a better way to produce steel, and he began experimenting with different methods. After many failed attempts, he developed the crucible steel process in the 1740s. This process involved melting iron in a clay crucible, along with a carefully measured amount of carbon. The mixture was heated to a high temperature, and then the crucible was removed from the furnace and allowed to cool slowly.

The result of the crucible steel process was a high-quality steel that was strong, durable, and resistant to breaking. This steel was ideal for use in tools, weapons, and other industrial applications, and it quickly became popular in England and throughout Europe. Huntsman’s crucible steel process was a major breakthrough in the production of steel. It was important to establish the way for the development of modern steel-making processes. Huntsman continued to refine his process over the years, and he became one of the most successful steel manufacturers of his time.

The Legacy of Benjamin Huntsman

Benjamin Huntsman’s contributions to the iron foundry industry were significant, and his legacy continues to this day. Huntsman’s crucible steel process revolutionized the production of steel, and it paved the way for the modern steel industry. His innovations also helped to drive the Industrial Revolution, as the use of steel in construction and manufacturing allowed for stronger and more durable buildings, machines, and tools.

Huntsman’s impact on the iron foundry industry can still be seen today in the numerous steel mills and foundries that exist around the world. The development of the crucible steel process led to the creation of new jobs and industries, and it helped to drive economic growth and prosperity.

Huntsman’s Additional Contributions

In addition to his contributions to the iron foundry industry, Benjamin Huntsman was also a philanthropist and a supporter of education. He established a charitable trust to provide funding for schools and other educational institutions, and he also supported research in the fields of chemistry and metallurgy.

Overall, Benjamin Huntsman was a pioneer in the field of steel production, and his legacy continues to inspire and influence the iron foundry industry to this day.

The Evolution of Iron Foundries

The Evolution of Iron Foundries

The iron foundry industry has evolved significantly since its early days, and modern foundries use a variety of technologies and processes to produce iron and steel products.

One of the most significant advancements in the iron foundry industry has been the use of computer-aided design and manufacturing (CAD/CAM) software. This technology allows foundries to create detailed digital models of their products, which can then be used to create precise molds and patterns for casting. CAD/CAM technology has helped to streamline the production process, reduce waste, and improve product quality.

Modern Innovations to the Industry

Another innovation in the iron foundry industry has been the use of induction furnaces. Induction furnaces use an electromagnetic field to heat metal, which allows for precise temperature control and faster heating times. This technology has helped to improve the efficiency of iron foundries, and it has also reduced energy consumption and emissions.

In addition to these technological advancements, the iron foundry industry has also made significant strides in sustainability and environmental responsibility. Many foundries now use recycled materials in their production processes, and they have implemented measures to reduce waste and emissions. This has helped to minimize the environmental impact of the iron foundry industry, while also improving efficiency and reducing costs.

A Legacy of Innovation

Today, iron foundries continue to evolve and innovate, using new technologies and processes to improve efficiency, reduce waste, and minimize environmental impact. The legacy of Benjamin Huntsman continues to inspire and influence the iron foundry industry, and his contributions to the field of steel production will be remembered for generations to come.

Choose Willman for Quality

Willman is proud of these innovators in the iron and steel industry. Without their contributions to these important industries, we would not have some of the things that we take for granted today. Our engineers, specialists, and technicians are inspired by their ingenuity and motivated to build on their success.

Call us today to find out how our dedication to excellence can benefit your company and your customers. Our knowledgeable staff and state-of-the-art facilities will provide the quality that you deserve!