Henry Cort and the Revolutionary Impact of the Iron Foundry

Henry Cort and the Iron Foundry

The iron foundry has played a pivotal role in the industrial revolution, and one name that stands out in the history of iron foundries is Henry Cort. Let’s explore the life of Henry Cort and his contributions to the development of iron foundries. We will examine his revolutionary innovations and their lasting impact on the industrial landscape.

The Early Life of Henry Cort

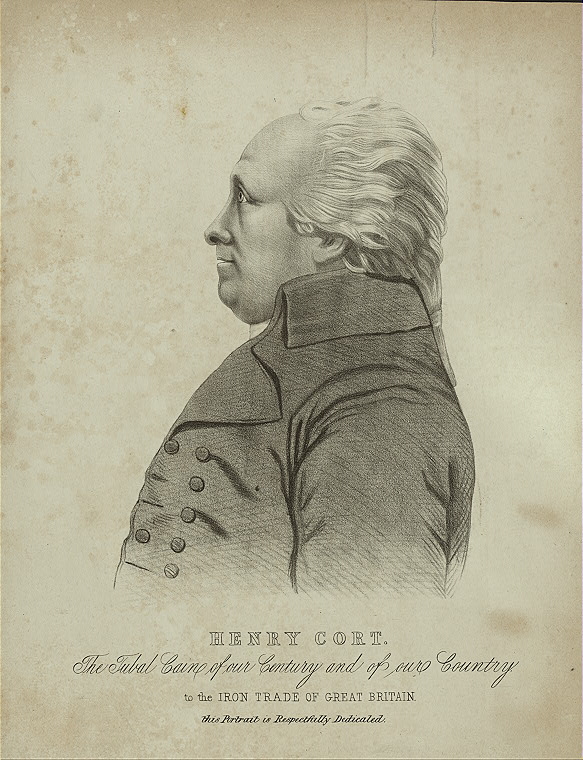

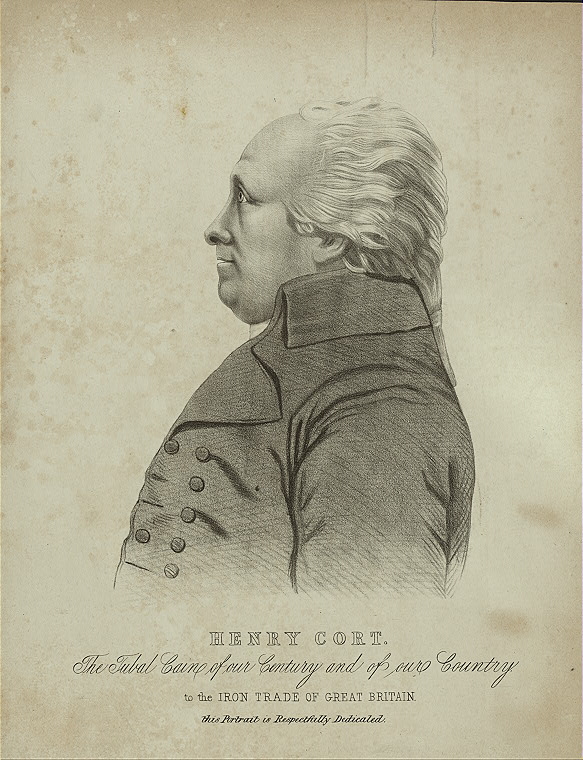

Henry Cort was born in Lancaster, England, in 1740. Little is known about his early life. However, his exceptional engineering skills and innovative mindset would later earn him the title of “Father of the Iron Trade.” Cort’s remarkable journey began in earnest when he entered the iron industry as an apprentice at the age of 17.

After serving for ten years as a civilian official for the Royal Navy, Cort left to go into business for himself. A shrewd investor, he had saved up a considerable sum during his years in public service. In 1775 he purchased an ironworks near Portsmouth, England. He focused his brilliant mind on the process and innovation of his iron foundry.

Importance of the Iron Foundry

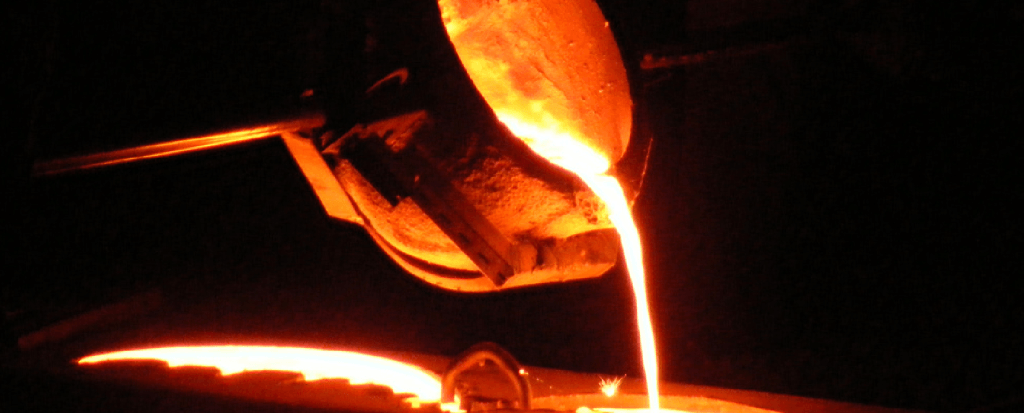

Iron foundries played a crucial role in the Industrial Revolution, offering several advantages over traditional methods of iron production. Foundries allowed for the centralized production of iron, facilitating economies of scale and streamlining the manufacturing process.

They also provided a controlled environment for casting iron into various shapes and forms, enabling the creation of complex and precise iron components. Henry Cort saw the importance of improving the end products of the foundry. With more uniform and stronger metal, the Industrial Revolution would rise to the next stage.

The Puddling Process

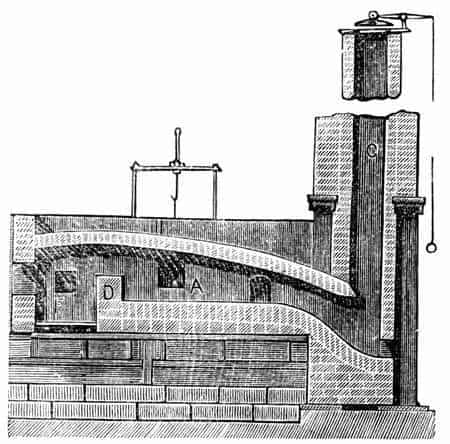

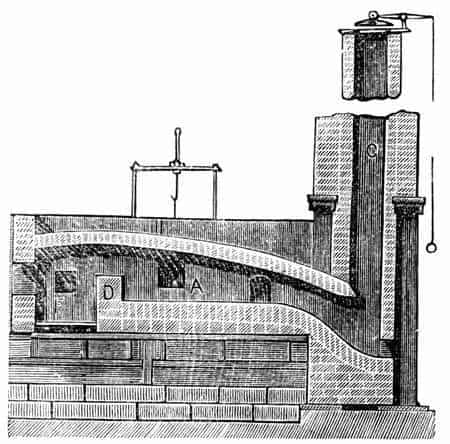

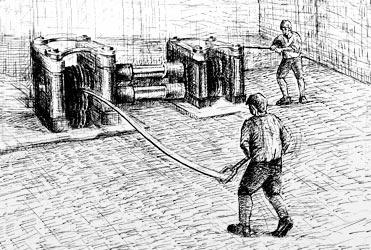

Schematic drawing of a puddling furnace,

Public Domain, https://commons.wikimedia.org/w/index.php?curid=551224

One of Henry Cort’s most significant contributions to the iron industry was the invention of the puddling process. Before Cort’s innovation, iron production was inefficient and time-consuming. Heating iron to the melting point had never been improved on in a thousand years. Impurities would remain in the iron, causing temperature differences. After the iron was formed, those same impurities would cause weakness and deformities in the final product.

The puddling process involved melting pig iron in a reverberatory furnace and stirring it to remove impurities. This technique produced wrought iron, which was stronger and more malleable than cast iron, making it suitable for a wide range of applications.

The Rolling Mill

In addition to the puddling process, Cort also revolutionized iron production with the introduction of the rolling mill. Prior to his innovation, iron was manually pounded into sheets and bars for use in other production. This manual process produced varying shapes and thicknesses.

In addition to the puddling process, Cort also revolutionized iron production with the introduction of the rolling mill. Prior to his innovation, iron was manually pounded into sheets and bars for use in other production. This manual process produced varying shapes and thicknesses.By combining the rolling mill with the puddling process, Cort created a highly efficient system for producing iron. The rolling mill allowed for the mass production of iron sheets and bars of uniform thickness, which greatly enhanced the versatility and affordability of iron products.

The Impact on Industrial Development

Henry Cort’s innovations had a profound impact on industrial development during the 18th and 19th centuries. The introduction of the puddling process and the rolling mill transformed the iron industry, leading to a significant increase in iron production. This surge in production fueled the growth of other industries, such as construction, transportation, and manufacturing, as iron became more readily available and affordable.

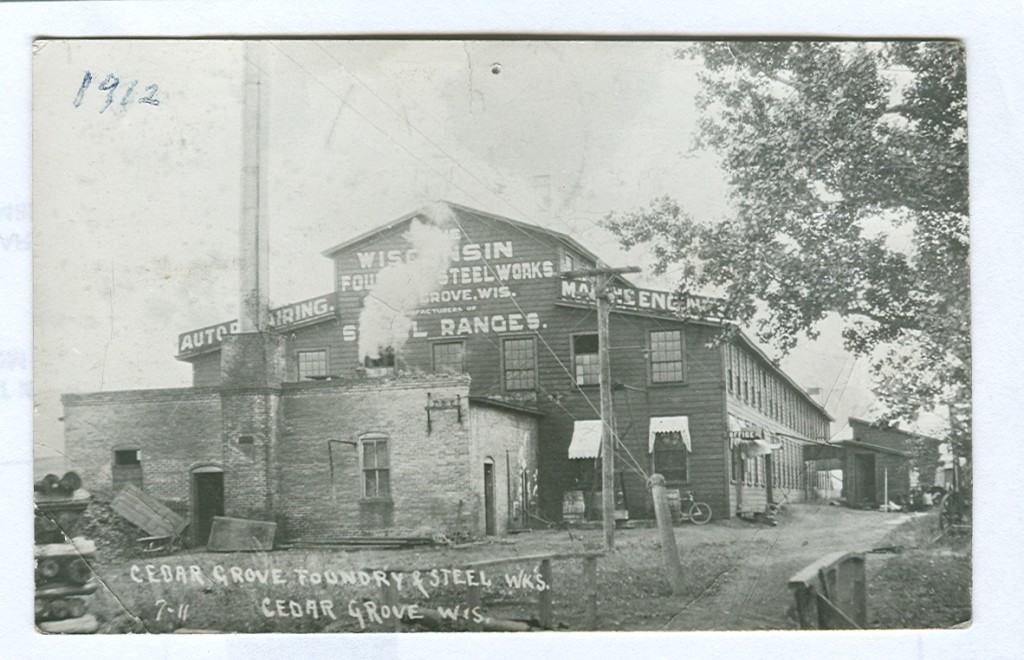

Expansion of Iron Foundries

The success of Henry Cort’s innovations led to the widespread adoption of iron foundries throughout Britain and other industrialized nations. Iron foundries sprang up in key manufacturing centers, such as Birmingham, Sheffield, and Manchester.

The success of Henry Cort’s innovations led to the widespread adoption of iron foundries throughout Britain and other industrialized nations. Iron foundries sprang up in key manufacturing centers, such as Birmingham, Sheffield, and Manchester.The expansion of iron foundries not only stimulated local economies but also fostered technological advancements and the exchange of ideas among ironworkers and engineers.

Legacy and Continuing Influence

Henry Cort’s legacy extends far beyond his lifetime. His pioneering contributions to iron foundries laid the foundation for modern iron and steel production techniques. His methods remained the standard for iron production well into the 19th century and formed the basis for subsequent innovations.

Even today, iron foundries continue to play a crucial role in the manufacturing sector, producing essential components for industries ranging from construction to automotive.

We Share Cort’s Pioneering Spirit

Henry Cort’s innovations in iron foundries were instrumental in driving the industrial revolution forward. His puddling process and rolling mill transformed the iron industry, leading to increased production, affordability, and versatility. Iron foundries became vital hubs of technological advancements, shaping the modern industrial landscape. Today, we owe much of our technological progress to Henry Cort’s pioneering spirit and his revolutionary contributions to iron foundries.

Henry Cort’s innovations in iron foundries were instrumental in driving the industrial revolution forward. His puddling process and rolling mill transformed the iron industry, leading to increased production, affordability, and versatility. Iron foundries became vital hubs of technological advancements, shaping the modern industrial landscape. Today, we owe much of our technological progress to Henry Cort’s pioneering spirit and his revolutionary contributions to iron foundries.Willman has long been inspired by innovators like Henry Cort. As we continue to rely on iron and steel for countless applications, we can appreciate the lasting impact of Cort’s innovations on the world around us.