Rene-Antoine Ferchault de Reaumer: Stoking the Fires of the Industrial Revolution

Innovation for the Iron Foundry at the Dawn of the Industrial Revolution

Rene-Antoine Ferchault de Reaumur was a French scientist who contributed significantly to the study of iron and iron foundries at the dawn of the Industrial Revolution. During his lifetime, he made many discoveries and inventions that helped to revolutionize the iron industry. In this article, we will explore the life and work of Rene-Antoine Ferchault de Reaumur and his contributions to the iron foundry industry.

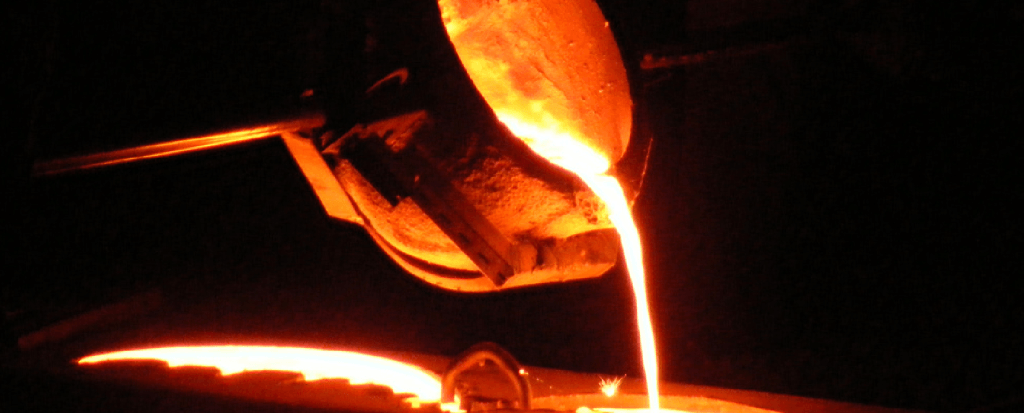

Iron foundries are facilities where iron is melted and cast into various shapes and forms. These foundries have been in existence for thousands of years, and their importance cannot be overstated. Iron foundries are used to produce everything from tools and weapons to machinery and infrastructure. They have played a crucial role in the development of human civilization, and continue to be an essential part of modern industrial processes.

Early Scientific Interest Led to a Lifelong Passion

Rene-Antoine Ferchault de Reaumur was born in La Rochelle, France, in 1683. He was a member of a noble family, and his father was a lawyer. As a young man, Rene-Antoine showed an interest in science and technology, and he went on to study these subjects at the University of Angers. After completing his studies, Rene-Antoine moved to Paris, where he became involved in the scientific community.

Rene-Antoine Ferchault de Reaumur was born in La Rochelle, France, in 1683. He was a member of a noble family, and his father was a lawyer. As a young man, Rene-Antoine showed an interest in science and technology, and he went on to study these subjects at the University of Angers. After completing his studies, Rene-Antoine moved to Paris, where he became involved in the scientific community.

Reaumur’s first significant contribution to the field of iron foundries came in 1722. He published a book titled “L’Art de Convertir le Fer Forgé en Acier,” which translates to “The Art of Converting Wrought Iron into Steel.” In this book, Reaumur described a process for converting wrought iron into steel by heating it in a clay crucible with powdered charcoal. This process was a significant improvement over the traditional methods of steel production, which involved heating iron in a furnace with charcoal.

Continuing Innovations for Iron Foundry Industry

Reaumur’s process was widely adopted by iron foundries throughout Europe and helped to increase the production of high-quality steel. It also helped to reduce the cost of steel production, making it more accessible to a wider range of industries. Rene-Antoine’s book was a groundbreaking work that helped to establish him as one of the leading scientists of his time.

In addition to his work on steel production, Rene-Antoine also made significant contributions to the study of metallurgy. He conducted experiments on the properties of various metals, including iron, and discovered that the addition of small amounts of certain elements, such as carbon, could significantly improve the strength and durability of iron alloys. This discovery led to the development of new types of iron alloys that were stronger and more durable than traditional iron.

Reaumur also studied the behavior of iron at high temperatures and discovered that iron could be hardened by quenching it in water or oil. This process, known as quench hardening, was another significant advancement in the field of metallurgy and helped to increase the strength and durability of iron-based alloys.

Paving the Way for a Revolution

Rene-Antoine’s work on iron foundries and metallurgy had a profound impact on the iron industry, and his discoveries and inventions helped to improve the quality and reduce the cost of iron production. His contributions helped to lay the foundation for the Industrial Revolution, which would transform the world and bring about significant advancements in science, technology, and industry.

Rene-Antoine’s work on iron foundries and metallurgy had a profound impact on the iron industry, and his discoveries and inventions helped to improve the quality and reduce the cost of iron production. His contributions helped to lay the foundation for the Industrial Revolution, which would transform the world and bring about significant advancements in science, technology, and industry.

Today, iron foundries continue to be an essential part of modern industrial processes. They are used to produce a wide range of products, including machinery, tools, and infrastructure. The techniques and processes developed by Rene-Antoine Ferchault de Reaumur and other scientists and engineers have been refined and improved over the centuries, and today’s iron foundries are highly efficient and technologically advanced.

Not Just a Metallurgist

Rene-Antoine Ferchault de Reaumur was not just a renowned metallurgist. He also studied animals and nature tirelessly. He found answers to mankind’s needs around every corner and in every nook. His study of wasps and their nests gave insight into innovations in the paper industry. His study of spiders and silk-making was so groundbreaking that the emperor of China had it translated into Chinese. He even standardized the measurement of temperature, using a scale that still bears his name.

Rene-Antoine Ferchault de Reaumur was not just a renowned metallurgist. He also studied animals and nature tirelessly. He found answers to mankind’s needs around every corner and in every nook. His study of wasps and their nests gave insight into innovations in the paper industry. His study of spiders and silk-making was so groundbreaking that the emperor of China had it translated into Chinese. He even standardized the measurement of temperature, using a scale that still bears his name.

Reaumur was a trailblazing scientist whose work on iron and iron foundries helped to transform the world. Before his death in 1757, his discoveries and inventions laid the foundation for the Industrial Revolution. They will continue to inspire and inform the modern iron foundry industry. As the world continues to evolve, iron foundries will remain an essential part of modern industrial processes, and the legacy of Rene-Antoine Ferchault de Reaumur will continue to inspire and inform future generations of scientists, engineers, and innovators.

Willman is the Right Answer

Willman is the Right Answer

If you are in need of iron foundry services, it is essential to choose a reputable and reliable provider. Look for a company with a proven track record of quality and customer satisfaction, as well as a commitment to sustainability and environmental responsibility. With the right partner, you can ensure that your iron casting needs are met with the highest level of quality and efficiency.

Where will you find such a partner? With Willman Industries, of course! We are committed to producing the best quality products as quickly as possible. We want our customers to be successful and we know that quality is the cornerstone to that success! Call us today to talk to one of our engineers about your project and needs. We are ready to answer your questions and get you going!